Page 6 of 20

Our freight carriers assume that when a customer provides a business name, the business

is open from 8AM-5PM Monday-Friday, the business is located at a commercial address,

and that the business does not have a home or any other living residences on the property.

We will not be responsible for redelivery charges to businesses that are not open during the

above mentioned hours when the first delivery attempt was made. Any redelivery or

residential delivery cost that are incurred due to misrepresentation or fault of the customer,

must be paid in full to us or the warranty on the respective product is void. Any storage

charges from the respective freight company must be paid in full before equipment will be

released for delivery. Any costs left unpaid will void the warranty. Customers are responsible

for unloading from delivery truck at time of delivery. Lift gate service cannot and will not be

provided for auto lift delivery.

ANCHORING TIPS

1. Concrete needs to be fully cured and a minimum of 4000 PSI compressive strength.

Thickness 4-6 inches in order to achieve minimum anchor embedme

nt of 3.25”. When

using the standard anchor bolts -

if the top of the embedded anchor exceeds 2.25”

above floor grade, you DO NOT have enough embedment.

2.

Use the holes in base plates as guide for drilling the ¾” holes needed. Do not drill over

an edge or a

seam or a crack. Hole to hole spacing should be a minimum 6.5” in any

direction. Concrete thickness or hole depth should be a minimum of 4”.

CAUTION: DO NOT install on asphalt or other similar unstable surface. Concrete

only. Columns are supported only by anchors in the floor.

3. Using the horseshoe shims provided, shim each column base until each column is

plumb. If one column has to be elevated to match the the other column, full size base

shim plates should be used (not provided).

4. Torque anchors to 120 ft-

lbs. Shim thickness MUST NOT exceed ½” when using the

supplied anchors with the lift.

5. If anchors cannot be torqued to 120 ft-lbs. then replace concrete under each column

base with a 4’ x 4’ x 6” thick 3,000 PSI minimum concrete pad keyed under, and flush

with, the top of the existing floor. Let concrete fully cure before installing lifts and

anchors.

6.

Anchors must be at least 6” from the edge of the slab or any seam.

7.

Use a concrete hammer drill with a ¾” carbide bit. Do not use excessively worn bits or

bits which have been incorrectly sharpened.

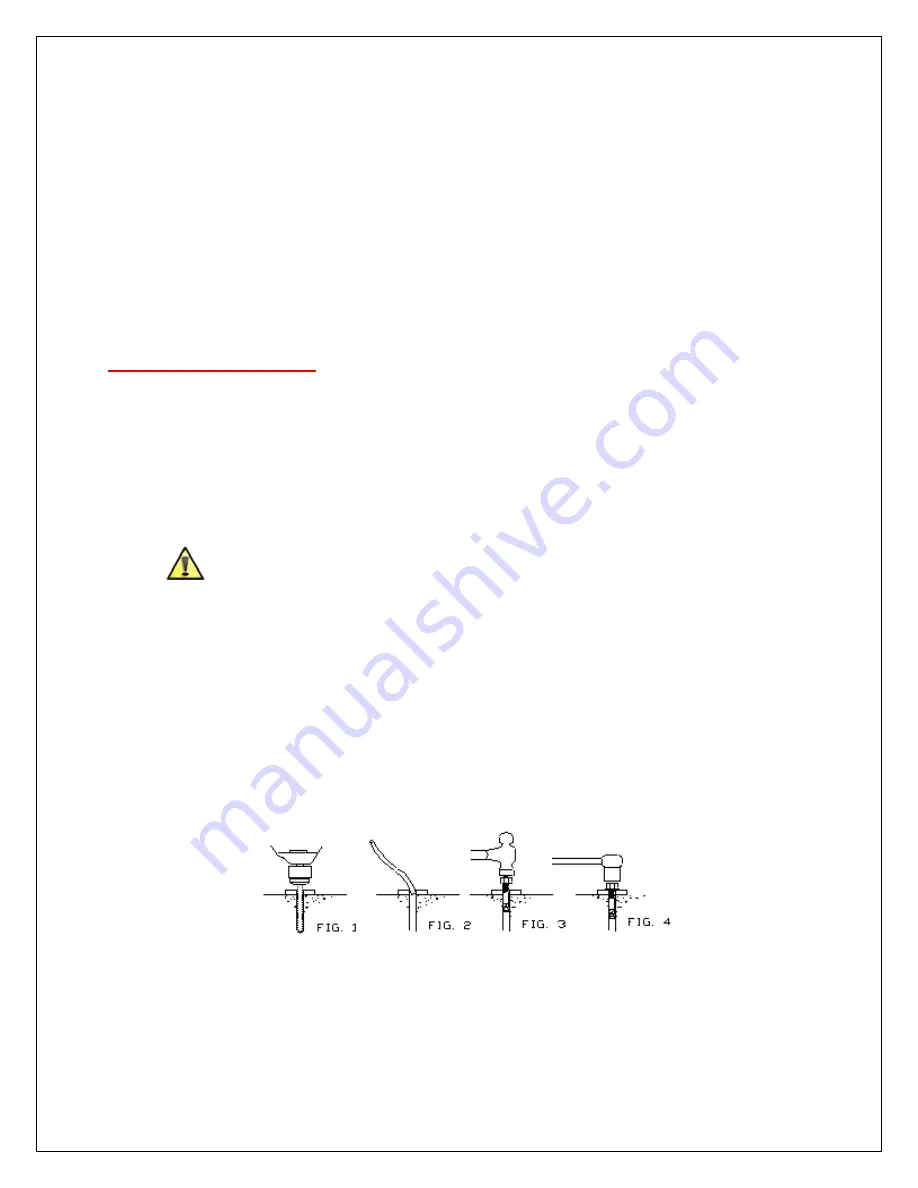

8. Keep the drill perpendicular while drilling.

Содержание NTO-10A

Страница 3: ...Page 3 of 20...