113

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

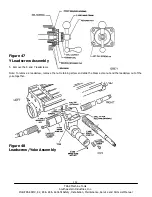

6. Remove the yoke from the saddle. Disconnect the oil lines from the yoke. If the yoke is to be re-used, it will be

necessary to remove the brass nut key and pins. If the kit came with a yoke, the original yoke may be discarded.

7.

Clean the X and Y-axis gibs, oil grooves and slideways thoroughly. Also remove the sliding covers and clean

them. Inspect the operation of the oiling system.

Note: Step 7 is worth extra care, especially with machines that have some wear, or new machines that may have some

protective covering on the ways. System performance depends on smooth motion.

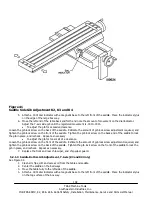

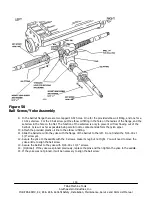

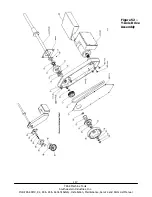

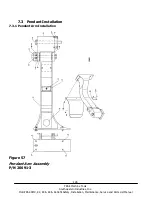

7.1.2 X-Axis Ball Screw Installation - Part 1

The ball screws are to be installed in the following order:

First - part of the X-axis ball screw assembly.

Second - the entire Y-axis ball screw assembly.

Third - the rest of the X-axis ball screw assembly.

Parts required:

Yoke kit 15844-xx

X-Axis drive kit 20255 -xx

X-Axis ball screw

Figure 49

X-Axis Ball Screw

Note: There are wrench flats on the X and Y ballscrews for convenience.

Caution!

Unlike a leadscrew, never unscrew a ball screw from its nut.

This will destroy the ball screw.

8.

Position the yoke in the saddle with the threaded hole on the left. Do not secure the yoke to the saddle yet,

you will need to lift the yoke to slide in the ball screw.