105

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

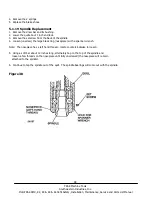

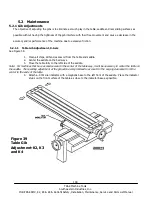

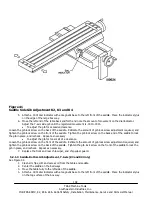

Every mechanical system has at least a little backlash or lost motion. It is produced by the small amount of play

between the gibs and ways, and mostly by the accumulative bending or elasticity of all the parts of the drive train under

load. The backlash constant is factory set, but may need to be adjusted periodically.

1.

Set a .0001-inch dial indicator in the spindle, and touch off on a block or the vise along the direction (X or

Y) you wish to check, or set the backlash constant.

2.

Turn on the ProtoTRAK and at the Main Menu, follow the procedure below precisely:

Conversation Says

You Do

a. ---

a. Press MODE

b. Select Mode

b. Press SET UP

c. Select

c. Press SERV CODES

d. Select

d. Press “B”

e. Select Code 127

e. Press X or Y

f. Backlash Value = _ _ _ _

f. What is shown is the current value.

Follow the instruction on the screen

and press the appropriate soft keys.

Wait a few seconds between each

INCR VALUE or DECR VALUE

press.

g. The following is an example of what you

might see when running this code.

For example, if the up and down "Oscillation

Value" shown in the conversation line is .00278

inch, and the dial indicator is moving back and

forth .0012, then the true backlash value is

.00278 -.0012 = .00158 inch. Input this by

pressing MODE, SET UP, SERV CODE, 128, SET

and then .00158, SET, RETURN.

3.

The X backlash identified and stored in Step 2 should be less than 0.003” on a new machine. If it is appreciably

larger, inspect the drive train for loose bolts, brackets, bearings, etc.

The backlash can also be found manually with a 0.0001” indicator with the following method.

Load the indicator to zero from one direction and zero out the DRO.

Move the indicator to 0.002” and then back to zero. Do not over shoot 0, otherwise start over.

Whatever number appears on the screen is the backlash value.

Enter this value into service code 128.

After entering this number redo the process. The DRO and indicator should now both read 0.

CODE 128: Input Backlash Constant

Code 128 allows you to enter the backlash values for each axis. It displays the value after it enters. This

code is only used on machines with single feedback.

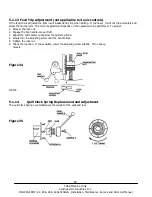

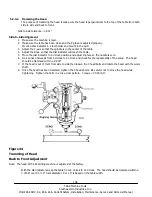

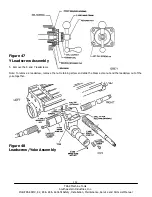

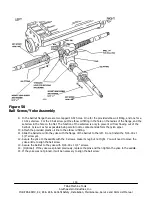

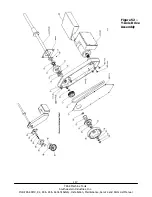

5.2.3 Head Rotational and Tramming

The TRAK knee head is free to rotate up to 90 degrees to the right or left. The K2 and K3 can also rotate 45

front to

back. The K4 machine cannot rotate front to back.

5.2.3.1 To Rotate the Head Side to Side:

1.

Loosen the four locknuts.

2.

Rotate the head with the adjusting worm shaft. When rotating to greater than a 45

o

angle, support head by

hand.

3. Tighten the locknuts. Snug each locknut, then lightly tighten each locknut, then fully

tighten each locknut in a crisscross pattern.

4. Use the method shown in the figure below and a parallel bar to square the head to the table.