Lubrication

Greasing the Front Wheel

Bearings

Service Interval:

Every 25 hours

Grease type:

General-purpose grease

1.

Park the machine on a level surface, disengage

the blade-control switch, and engage the parking

brake.

2.

Shut off the machine and remove the key.

3.

Clean the grease fittings with a rag.

Note:

Make sure to scrape any paint off the

front of the fitting(s).

4.

Connect a grease gun to the fitting.

5.

Pump grease into the fittings until grease begins

to ooze out of the bearings.

6.

Wipe up any excess grease.

g343313

Figure 24

Electrical System

Maintenance

Maintaining the Batteries

Note:

The original batteries are maintenance-free

and do not require service.

WARNING

Battery terminals or metal tools could short

against metal components causing sparks.

Sparks can cause the battery gases to

explode, resulting in personal injury.

•

When removing or installing the battery,

do not allow the battery terminals to touch

any metal parts of the machine.

•

Do not allow metal tools to short between

the battery terminals and metal parts of the

machine.

•

Use insulated tools when maintaining the

batteries.

•

Always keep the battery retainers in place

to protect and secure the batteries.

DANGER

Do not touch any electrical components or

contacts on the motor.

Touching any of these components or

contacts could seriously injure you or cause

death.

Cleaning the Batteries

Service Interval:

Every 25 hours

1.

Ensure that all the battery caps are tight.

2.

Use a paper towel to clean the batteries.

3.

If the battery terminals are corroded, clean them

with a solution of 4 parts water and 1 part baking

soda. Also, clean the posts and cable clamps

with a post and clamp cleaner.

Note:

The posts and clamps should have a

bright, metallic shine.

4.

Apply a light coating of Toro battery-terminal

protector.

25

Содержание 75500

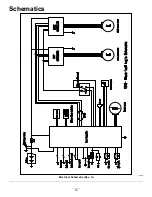

Страница 33: ...Schematics g355680 Electrical Schematic Rev A 33 ...

Страница 34: ...Notes ...

Страница 35: ...Notes ...