TK 61555-2-MM-EN

61

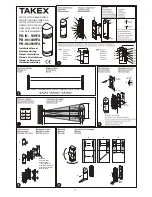

Figure 35.

Injection Pump Gear Tool

1.

Injection Pump

5.

Adapter (Tool)

2.

Gear Case

6.

Tool Long Screw (Tool)

3.

Cover Plate

7.

Tool Short Screw (Tool)

4.

Cover Plate Bolt

8.

Tool Plate (Tool)

Injection Pump Reinstallation

1. Position injection pump shaft into gear, rotating shaft to mate key with keyway in gear. Take

care to make sure the key mates with the keyway.

2. Secure injection pump to gear case with previously removed hardware. Make sure to align

the index marks on the injection pump and the gear case like they were in step 1 of

N

No

otte

e:: If a different injection pump is being installed, see

“Injection Pump Timing,” p. 53

to

set the timing.

3. Remove hardware holding gear to tool plate, then remove tool plate.

4. Secure the gear to the injection pump shaft with the lock washer and nut. Use a shop rag, as

before, to prevent the lock washer or nut from falling into the gear case. Torque the nut to 78

to 88 N•m (58 to 65 ft-lb).

5. Fasten cover plate to gear case and reinstall all components removed previously to facilitate

injection pump removal.

Fuel Solenoid Replacement

1. Disconnect the fuel solenoid wire connector from the main/unified wire harness and remove

the old fuel solenoid.

2. Connect the new fuel solenoid wire connector to the main/unified wire harness.

3. Press the ON Key to turn the unit on.

4. Use the microprocessor keypad to enter the Interface Board Test Mode. Refer to the

appropriate Microprocessor Diagnostic Manual for specific information about the Interface