MAINTENANCE

3-17

550E MM149 (6--96)

TO ADJUST SCRUB BRUSH PATTERN

1. The machine must have correct tire

pressures, full solution tank, and correct

scrub head height adjustment.

2. On a smooth, level surface, apply chalk or

some other material that won’t blow away

easily.

3. With the scrubber head raised, move the

machine over the test area. Start the brush

rotation, apply the foot brakes, and lower the

scrubber head, allowing the brushes to spin

in one spot for 15 to 20 seconds. With no

chalk or other material on the floor, allow the

brushes to spin approximately two minutes.

4. Polish marks made by both brushes should

be visible. They should be about 1.5 in

(40 mm) wide the full length of the brush.

With a soft brush, the polish mark should not

exceed 2 in (50 mm) wide, evenly, the full

length of the brush.

5. The rear brush polish mark is the most

critical and should be adjusted first. If the

polish mark is uneven or cone shaped from

one end to the other, the brush leveling

spring, located at the operator side of the

head lift, should be adjusted. The spring

compensates for the weight of the brush

drive motors. Loosen the top nut first to

make the adjustment.

B

C

A

00285

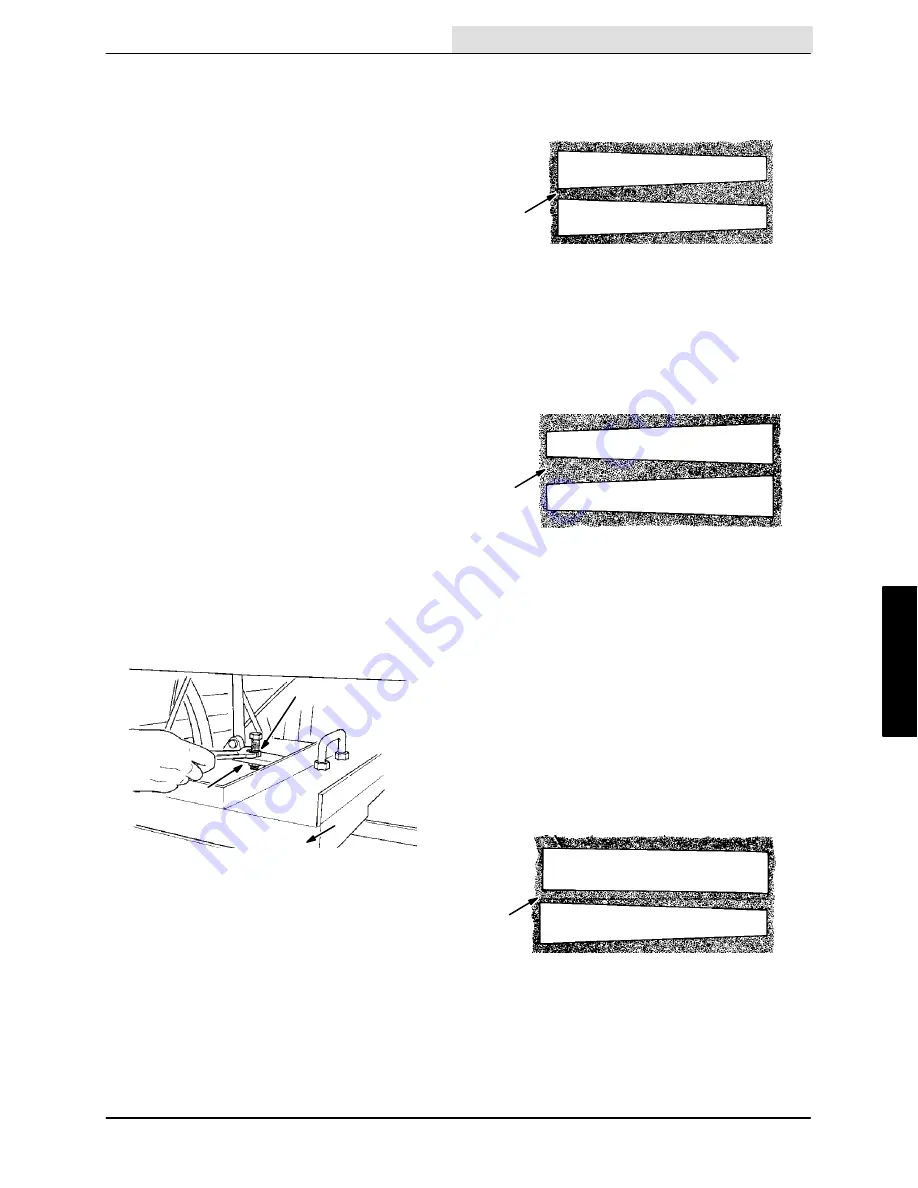

LEVELING BRUSH

A. Top Nut

B. Brush Levelling Adjusting Nut

C. Operator Side of Scrub Head

Lower the brush leveling adjustment nut if

the polish mark is too wide on the operator’s

side.

A

00082

TAPERED BRUSH PATTERN

A. Operator Side

Raise the brush leveling adjustment nut if

the polish mark is too narrow on the

operator’s side. Retighten the top nut after

making adjustments.

A

00082

TAPERED BRUSH PATTERN

A. Operator Side

6. The polish mark of the front brush should

match the polish mark of the rear brush. If

the front brush polish mark is uneven, the

narrow side should be shimmed. Add shims

to the shaft bearing mount located on the

underside of the scrub head. Remove the

debris trough, loosen the bolts holding the

bearing protector, and loosen the flat socket

head bolts that hold the bearing mounting

bracket before installing shims. One 0.12 in

(3 mm) thick shim will add about 0.50 in

(13 mm) width to the polish mark.

B

A

C

00082

TAPERED BRUSH PATTERN

A. Operator Side

B. Rear Brush Marks

C. Front Brush Marks

Содержание 550

Страница 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Страница 12: ...OPERATION 550E MM149 3 91 2 2 ...

Страница 30: ...OPERATION 550E MM149 9 00 2 20 ...

Страница 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Страница 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Страница 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Страница 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Страница 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Страница 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Страница 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Страница 108: ...STANDARD PARTS 550E MM149 5 01 6 38 Fig 24 Power Wheel Group 2 3 4 5 6 1 5 Hydraulic Brake Assembly ...

Страница 110: ...STANDARD PARTS 550E MM149 5 01 6 40 Fig 25 Electrical Wire Harness Group 1 2 3 4 5 6 7 8 9 10 11 12 13 ...

Страница 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Страница 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Страница 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Страница 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...

Страница 196: ...CROSS REFERENCE 550E MM149 10 10 10 14 ...