Optical Sampling Modules

4–96

CSA8000 & TDS8000 Instruments and Sampling Modules

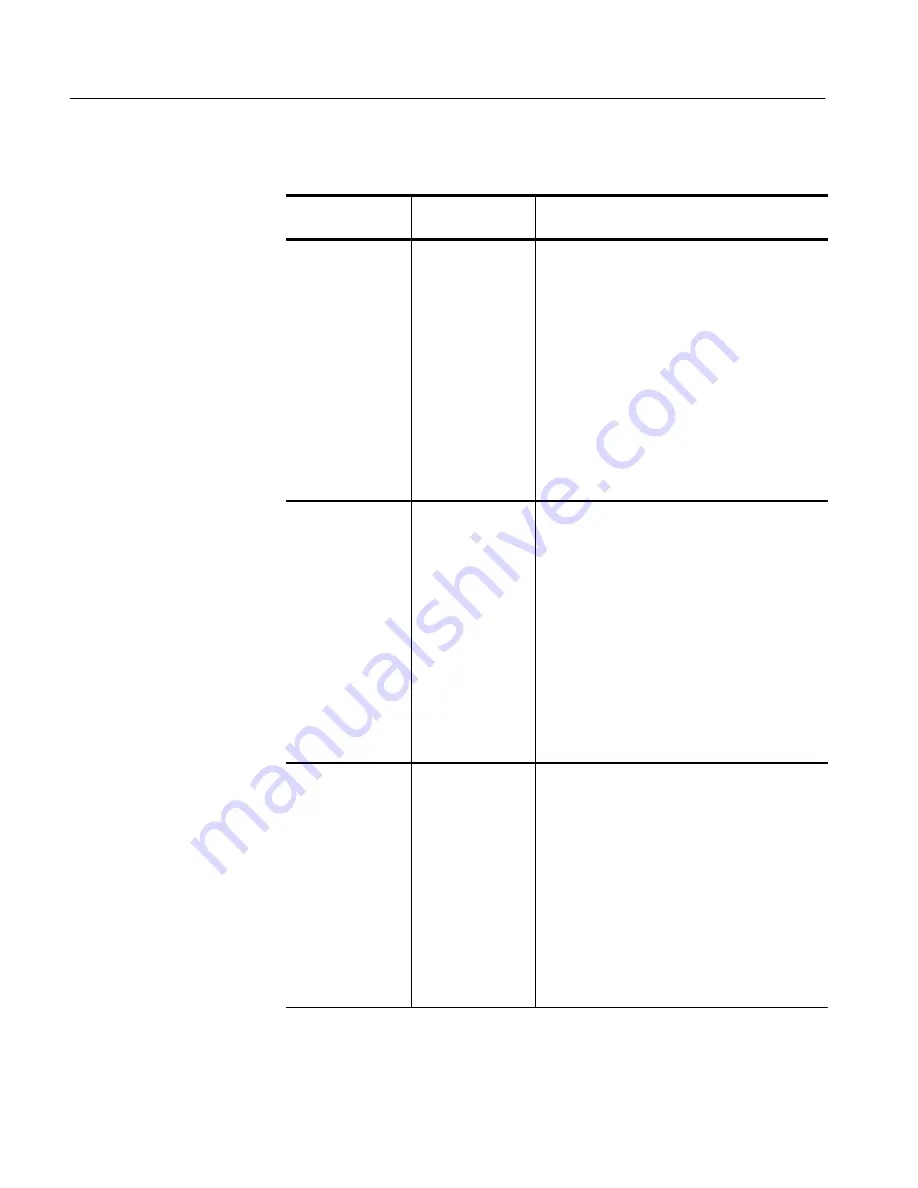

Table 4–9: Reference receiver frequency response limits

Optical

sampling module

Filter

Limits

80C01

OC-12/STM-4

(MHz)

(dB)

Frequency

Lower

Nominal

Upper

0.000

–0.50

0.00

+0.50

93.3

–0.61

–0.11

+0.39

186.6

–0.95

–0.45

+0.05

279.9

–1.52

–1.02

–0.52

373.2

–2.36

–1.86

–1.36

466.7

–3.50

–3.00

–2.50

559.9

–5.67

–4.51

–3.35

622.1

–7.25

–5.71

–4.17

653.2

–8.08

–6.37

–4.66

746.5

–10.74

–8.54

–6.35

839.8

–13.55

–10.93

–8.31

933.1

–16.41

–13.41

–10.41

1244.2

–26.11

–21.45

–16.78

80C01, 80C03

OC-48/STM-16

(MHz)

(dB)

Frequency

Lower

Nominal

Upper

0.000

–0.50

0.00

+0.50

373.3

–0.61

–0.11

+0.39

746.5

–0.95

–0.45

+0.05

1119.7

–1.52

–1.02

–0.52

1493.1

–2.36

–1.86

–1.36

1866.3

–3.50

–3.00

–2.50

2239.5

–5.67

–4.51

–3.35

2488.3

–7.25

–5.71

–4.17

2612.8

–8.08

–6.37

–4.66

2986.0

–10.74

–8.54

–6.35

3359.3

–13.55

–10.93

–8.31

3732.6

–16.41

–13.41

–10.41

4976.7

–26.11

–21.45

–16.78

80C01,

80C02,

8

0C04, 80C05

OC-192/STM-64

(MHz)

(dB)

Frequency

Lower

Nominal

Upper

0.000

–0.85

0.00

+0.85

1493.2

–0.96

–0.11

+0.74

2986.0

–1.30

–0.45

+0.40

4478.8

–1.87

–1.02

+0.17

5972.4

–2.71

–1.86

–1.01

7465.0

–3.86

–3.00

–2.16

8958.0

–6.19

–4.51

–2.83

9953.28

–7.87

–5.71

–3.55

10451.2

–8.75

–6.37

–3.99

11944.0

–11.53

–8.54

–5.56

13437.2

–14.45

–10.93

–7.41

14930.4

–17.41

–13.41

–9.41

Содержание CSA8000 Series

Страница 4: ......

Страница 18: ...Service Safety Summary xiv CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 22: ...Preface xviii CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 23: ......

Страница 59: ...80C00 Modules Specifications 1 36 CSA8000 TDS8000 Instruments and Sampling Modules back ...

Страница 63: ...80A01 Module Specifications 1 40 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 64: ......

Страница 74: ...Installation 2 10 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 93: ......

Страница 103: ...Theory of Operation 3 10 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 104: ......

Страница 106: ...Performance Verification Procedures 4 2 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 122: ...Brief Procedures 4 18 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 126: ...Performance Tests 4 22 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 218: ...80A01 Trigger Preamplifier Module 4 114 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 219: ......

Страница 231: ...Maintenance 6 6 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 291: ...Removal and Installation Procedures 6 66 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 307: ...Repackaging Instructions 6 82 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 308: ......

Страница 313: ......

Страница 315: ...Electrical Parts List 8 2 CSA8000 TDS8000 Instruments and Sampling Modules ...

Страница 316: ......