RUN 600 XTPRO: Service & Maintenance Manual - rev. 1.3

Page 8.4

8.4. ADJUSTING THE TENSION AND ALIGNMENT OF THE

TREAD-BELT MOTOR BELT

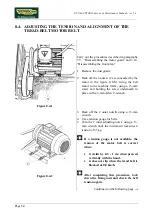

Figure 8.4-1

Carry out the procedures described in paragraphs

7.9. “Disassembling the motor guard” and 7.10.

“Disassembling the front plate”.

1. Remove the dust guard.

2. Back off the 4 nuts

a

(2 are concealed by the

motor in the figure at left) fixing the belt

motor to the machine frame, using a 13-mm

screw and holding the screw underneath in

place with a 6-mm Allen T-wrench.

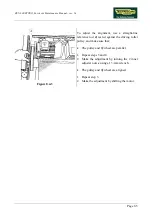

Figure 8.4-2

3. Back off the 2 outer nuts

b

using a 13-mm

wrench.

4. Use a tension gauge for belts.

5. Turn the 2 inner adjusting nuts

c

using a 13-

mm wrench until the instrument measures a

tension of 35 kg.

If a tension gauge is not available, the

tension of the motor belt is correct

when:

•

it yields by 0.5 - 1 cm when pressed

vertically with the hand.

•

it does not slip when the tread belt is

blocked at 0.8 km/h.

After completing this procedure, lock

down the fixing nuts and check the belt

tension again.

Continued on the following page

→

Содержание RUN 600 XTPRO

Страница 1: ...SERVICE MAINTENANCE MANUAL REV 1 3...

Страница 2: ......

Страница 4: ......

Страница 24: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 2 14 Page intentionally left blank...

Страница 36: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 3 12 Page intentionally left blank...

Страница 38: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 4 2 Page intentionally left blank...

Страница 82: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 6 42 Page intentionally left blank...

Страница 126: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 8 10 Page intentionally left blank...

Страница 156: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 11 14 Page intentionally left blank...

Страница 157: ......