2-3

2. MAIN UNIT REPLACEMENT

EO18-33002A

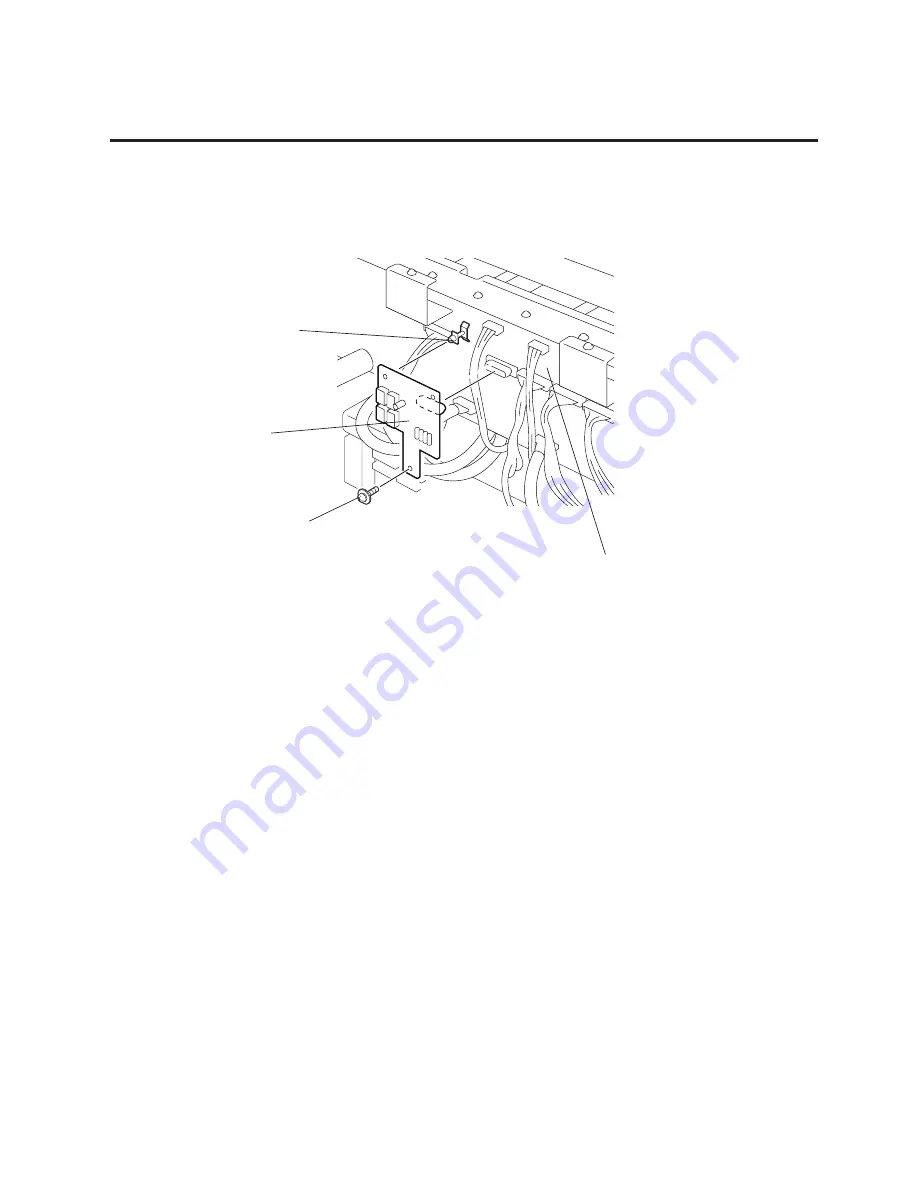

2.2 REPLACING THE HCHK PC BOARD

2.2 REPLACING THE HCHK PC BOARD

1) Remove the SMW-3x6 screw from the HCHK PC board.

2) Release the HCHK PC board from the locking support.

Locking Support

Fig. 2-3

3) Replace the HCHK PC board with a new one, and then reassemble in the reverse order of removal.

SMW-3x6 Screw

Driver PC Boared

HCHK PC Board