page

3

January 2020 - Rev. 1.2

Order Cod. 1902503003

1. General characteristics

The

Quad Microstep drive

unit is designed to control

and monitor up to four two-phase stepper motors,

operating in bipolar chopper mode.

The drive is equipped with a high performance trajectory

generator and with a digital control system of the

current supplied to ensure smooth and silent motor

movement.

Microstepping generation is achieved digitally and

is configurable remotely, as well as all the operating

parameters that can be varied via the field bus in use

(the use of configuration jumpers or the like is not

required).

The drive is always equipped with a

master

board

containing the global control electronics and the power

section for two motors; an

expansion

board is connected

to the master board and allows to control two additional

motors. The expansion board also provides 16 digital

24V isolated outputs and 16 digital inputs.

A front display and keyboard allow to rapidly view

the main configuration parameters and status of the

drive.

The general characteristics of the system are:

•

Open type

•

Limited dimensions: 375×190×80

•

High performance thanks to the use of Mosfet in

the power stage

•

Silent due to an operating frequency equal to

25KHz

•

Complete work parameter setting from remote

•

Front display and keyboard to verify some

operating parameters

•

Management of step fractionation up to 1/256

steps per step (for example, with motors operating

at 200 steps/revolution one can achieve positioning

resolutions up to 51200 microsteps/revolution).

The use of microstepping also allows to obtain less

motor heating and increased silentness in rotation.

The maximum generated frequency is in any case

equal to 622500 microstep/s

•

Optimal integration between the control stage,

power stage and inputs-outputs: in fact the

Microstep unit features a PMD indexer integrated

on-board, capable of handling 4 independent axes

with trapezoidal, velocity and S-curve profiles

•

16 digital 24V isolated inputs and 16 outputs

•

Control of stepper motors at 25V - 160V

max

and 1A

- 13A

•

Guards:

• Protection against short-circuit between the motor

phases

• Protection against incorrect wiring (phases not

connected)

• Protection against overtemperature

• Protection against short-circuit between a phase

and the drive power supply

•

Fault management and report

•

Remote reading of the power stage temperature

•

Remote reading of the motor supply voltage

•

Report of failure to reach the current set-point

while in motion.

•

UL certified

2. Technical specifications

2.1 Electrical ratings

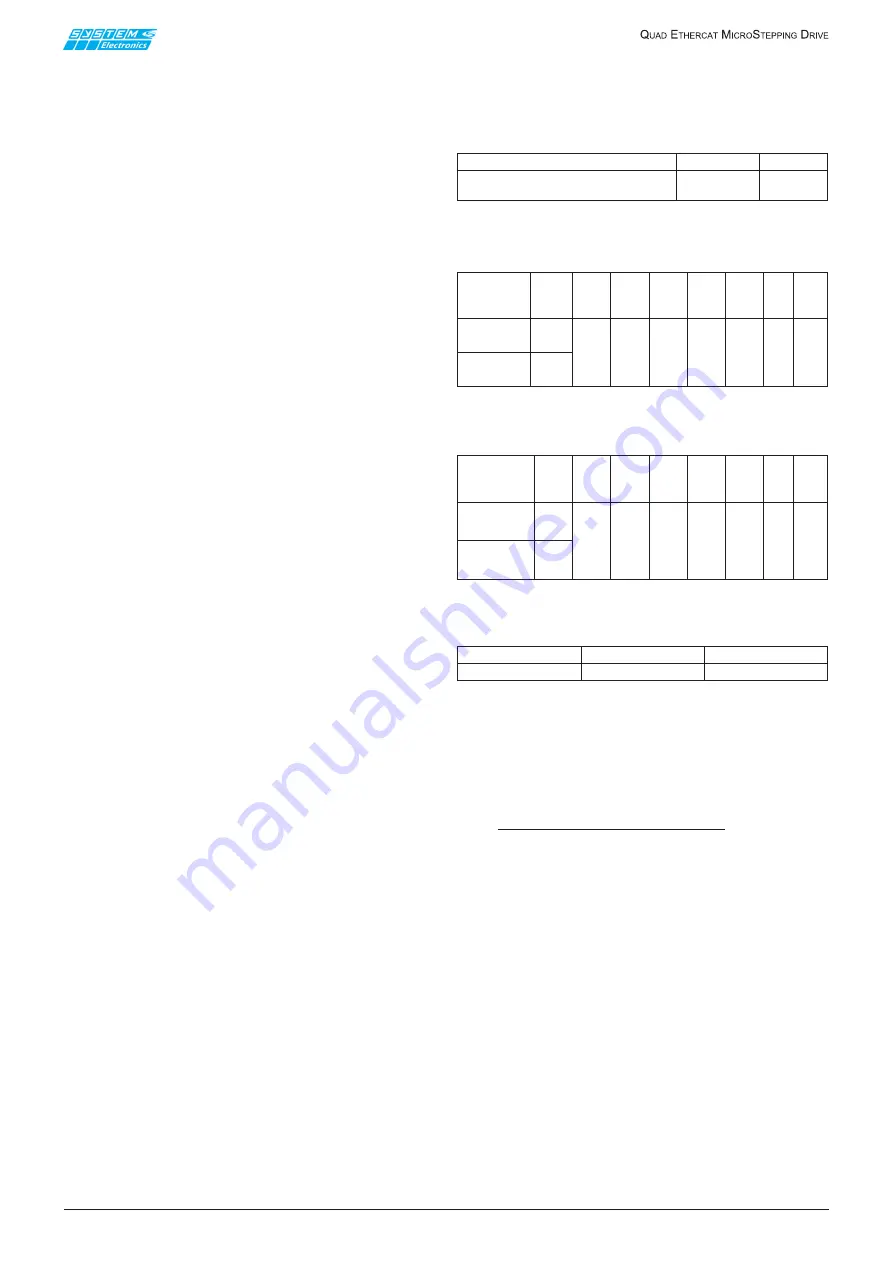

1. Power Input

Terminal

Voltage

Current

+V34-GND (XT2, pin B1,B2,B3,B4)

+V12-GND (XT1, pin B10,B11,B12,B13)

160Vdc

7A

Table 2.1.1

2. Power Output

Table 2.1.2

3. OPTIONAL Power Output

Table 2.1.3

4. Control Supply 24V Input

Table 2.1.4

Power supply separated and isolated from the control

power supply and I/O

•

Motor power supply min 25V max 180V. Separate

motor power supply for pairs of motors 1-2 and 3-

4:

while maintaining the same mass

, it is possible

to power motors with different voltages or partly

disable them

•

The power supply of the pair of motors 1-2 shares

the same GND of the pair of motors 3-4. The GND

can be connected to the PE depending on the

application

•

Power section operating temperature max 90°C

•

Minimum operating temperature 0°C

•

Reading via field bus of the power stage dissipators

temperature of each pair of motors

Temperature readings “1” and “2” refer to the pair

of motors 1 - 2; temperature readings “3” and “4”

to the pair of motors 3 - 4 (motors 1 and 2 share

the same dissipator, just as motors 3 and 4)

•

Programmable setting of the dissipator

overtemperature threshold (<90°C)

•

Remote reading of the motor supply voltage

•

Protection of every single motor with fuse on the

removable front terminal board. Fuse installed:

10A F 250V

(See par. 2.6 for details)

Terminal

Output

Voltage

Current

(Arms)

per

terminal

Max

two

phases

output

current

Peak

Current

Freq.

Power

Duty

Cycle

AN1-A1-BN1-B1

XT1, pin B6,B7,

B8,B9

AN2-A2-BN2-B2

XT1, pin B2,B3,

B4,B5

Motor 1

Motor 2

Max

160Vac

7A

Max

13A

Max

155KHz

2.7hp

10A

RMS

0-100%

Terminal

Output

Voltage Current

Max

two

phases

output

current

Peak

Current

Freq.

Power

Duty

Cycle

AN3-A3-BN3-B3

(XT2, pin B9,

B10,B11,B12)

AN4-A4-BN4-B4

(XT2, pin B5,

B6,B7,B8)

Motor 3

Motor 4

Max

160Vac

7A

Max

13A

Max

155KHz

2.7hp

10A

RMS

0-100%

Terminal

XP10

Voltage

24 Vdc

Current

0.5A