page

15

January 2020 - Rev. 1.2

Order Cod. 1902503003

For example, if one wants to obtain a speed of 50000

microstep/s

2

, one must calculate the following:

The parameters with one jerk dimensions (first derivative

of acceleration) must be intended as unsigned 32-bit

integers; these integers (actually fixed point numbers

in format 0:32) are obtained by multiplying by 2

32

) the

number of microsteps/cycle

3

.

For example, if one wants to obtain a jerk of 500

microstep/s

3

, one must calculate the following:

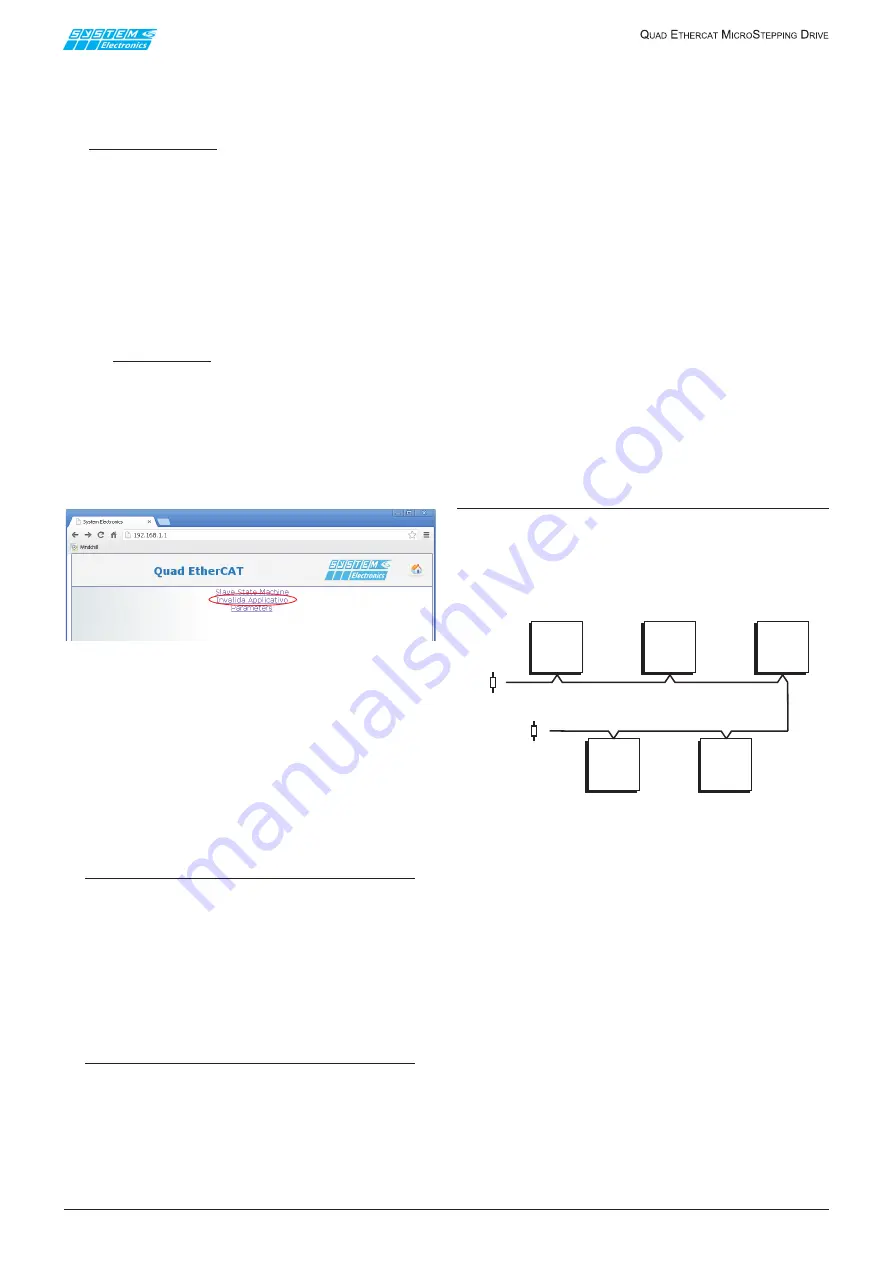

7. WEB interface

The axes management firmware contains a web server

that allows to interface the drive with any browser.

Figure 7.1

From the Home Page one can access three different

pages:

1.

“Firmware invalidation” and “drive reset” page.

This page is very useful if one wants to update the

axes management firmware via the browser.

2.

Management page (partial) of the drive automaton

state.

3.

Web controlled movements management page.

NOTE:

The use of the last two pages listed requires the

drive being set (via the front keypad) in CANopen

communication mode (actually, CANopen/

Ethernet) and is strongly unadvised. Ethernet/

HTTP communication, in fact, is not real-time

and is not recommended for controlling motors;

it is only envisaged as an internal tool for System

Spa developers.

NOTE:

Do not connect the Ethernet cable during normal

operation of the drive and replace the connector

protection cap at the end of the operation.

8. CANopen interface

The drive is equipped with a CAN communication port

and is designed to operate as a CANopen node and it

is actually allowed to set (via the front keypad) the

CANopen communication mode, as well as the CANopen

node address, the bit rate (between 10 kbps and 1

Mbps), the insertion of the termination resistor and

the slope control (in the event the transmission rate is

particularly high, i.e. above 500 kbps).

At present, however, there is NO CANopen object

implemented that allows the use of the drive for axes

management.

Default configuration:

•

Transmission speed 500Kbit

•

Termination NOT inserted

•

Slope inserted

For settings refer to paragraphs 3.2.5, 3.2.6 and

3.2.7.

Connection to the CAN network

The physical medium used for the connection is a

shielded two-wire cable. The arrangement of the nodes

must be such that the termination resistors are placed

at the two ends of the network; it is also advisable to

make the connections avoiding T connections.

Figure 8.1

120 ohm

120 ohm

Acceleration = 50000 microstep/s

²

50000 * 65536

3906.25

²

= 214 (format 16:16)

Jerk = 500 microstep/s

²

500 * 2

³²

3906.25

³

= 36 (format 0:32)