600m

m

600m

m

700m

m

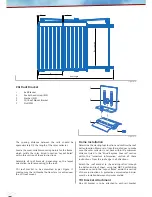

Figure 7

Regulations & OH&S

Before starting installation of the solar collector/s, the

installer should ensure they have read the “Important

Information” section of these instructions and are

familiar with the relevant standards, OH&S regulations

and safety precautions.

It is the builder’s responsibility to ensure the existing

house structure is adequate to take the additional loads

of the SolarCore

TM

Hot Water System.

Installation Procedure

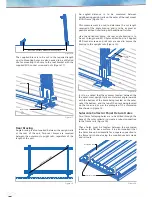

The solar collectors are mounted on a metal roof using

the same assembly procedure as outlined for tiled roofs

in section “Installation Procedure - Tiled Roof” of these

instructions.

Instead of lifting tiles, the stainless steel straps are

fastened through the roof cladding into the roof battens

as shown in Figure 8. The position of roof battens is

identified by the rows of fasteners on the roof.

Protect the gutter from being damaged by ladders, tools

and the solar collectors. Additionally, care should be

taken to avoid scratching Colorbond roofing while lifting

and positioning the solar collectors.

Fasten the top and bottom stainless steel straps to the

roof batten using two self drilling wood screws or metal

screws as shown in Figure 9.

It is important that the correct fasteners are used to

suit the purlin material. Incorrect fasteners may become

loose over time, resulting in an unsafe installation.

INSTALLATION PROCEDURE - METAL ROOF

Cover the hot temperature sensor with thermal paste and

insert it into the orifice provided near the water outlet of

the last solar collector. Push the hot temperature sensor

in fully with a screwdriver and seal the opening of the

orifice with a small amount of silicon.

Run the hot temperature sensor leads under a tile into

the roof space and down to the solar pump controller but

do not connect at this stage. Ensure the hot temperature

sensor leads are not in contact with the water pipes at

any point and fasten to framework with cable ties as

necessary.

Leave the plastic cover/s in place until commissioning

the solar hot water heating system.

It may be necessary to use packers underneath the top

frames to achieve proper alignment of the compression

union between the water outlet of the first solar collector

and water inlet of the second solar collector.

Repeat the above steps as necessary if more solar

collectors are being installed.

Once all solar collectors are in place, remove sufficient

tiles from above the tiles supporting the top frame/s.

Lift the top frame/s slightly, hook the top stainless steel

straps onto the top frames and attach the retaining

plates to the top stainless steel straps using the screws

and nuts provided. The top stainless steel straps should

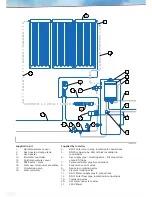

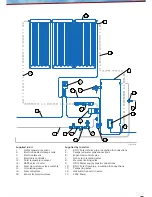

be spaced as shown in Figure 7.

Fit elbow compression fittings to the water inlet of the

first solar collector and hot water outlet of the last solar

collector. Penetrate the roof, connect the water pipes

with compression fittings and tighten.

Lower the top frame of the solar collectors back onto the

roof and packers. Fasten the top stainless steel straps to

the roof battens using three self drilling wood screws or

metal screws per strap, as shown in Figure 7.

Replace the tiles over the top stainless steel straps and

ensure they seat correctly.

Flash or seal the water pipe penetrations and the tiles (if

required).

Fasten the bottom stainless steel straps to bottom solar

collector frames with two screws per strap.