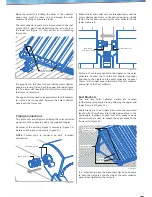

Pipe mount the circulation pump, with valves attached,

at a suitable location in the solar collector flow pipe

as outlined in “Installation of Circulation Pump” of

these instructions. Please refer to the manufacturer’s

instructions for the circulation pump installation details.

Run the circulation pump power cable to the electronic

controller and connect it to the pump terminals specified

in the manufacturer’s instructions for the electronic

controller.

Fit the solar collector return pipe and insulation

between the water outlet of the last solar collector and

the connection marked “solar return” on the hot water

storage tank. Cover the cold temperature sensor with

thermal paste for improved heat conduction. Fit a tee

and sensor immersion sleeve to the cold water inlet of

the tank and insert the cold temperature sensor. Tighten

the gland nut until the sensor cable is sealed firmly.

Run the cold temperature sensor lead to the temperature

differential controller and connect it to the cold

temperature sensor terminals as in the manufacturer’s

instructions for the temperature differential controller.

Ensure the cold temperature sensor lead is not in contact

with the hot water pipes at any point and fasten to

framework with cable ties as necessary.

Connect 15mm copper tube drain lines to the drain

outlets of the ECV and P&TR valves. Drain lines must be

open to atmosphere and slope continuously down to a

visible drain point, preferably over a drain. Drain lines

must be less than 9 metres long, free of restrictions and

other valves and positioned to prevent freezing.

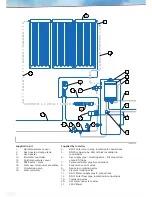

Fit the mains water supply pipe from the mains water

supply to the cold water inlet of the hot water storage

tank and purge before final connection to remove air and

swarf. Fit the hot water supply pipe from the hot water

outlet of the hot water storage tank to the pipe supplying

hot water to the building. A temperature limiting device is

required as outlined in “Water Pipes, Valves and Fittings”

within this section of these instructions.

Connect the power supply wires from the switch board,

as outlined in “Electricity Supply” within this section of

these instructions, directly to the terminal block and

earth tab connections inside the electrical cover of the

hot water storage tank. Use a flexible 20mm conduit and

connect with a 20mm terminator.

The electricity supply for single element heaters can

be either off-peak, extended off-peak or continuous

depending on tariffs available from the local electricity

supply authority. The thermostat should be set at 60°C

in accordance with Australian Standards.

Please refer to the manufacturer’s instructions for the

electric boosted hot water storage tank wiring diag.

& connection details. The installation of the electric

boosted Stratco Solarcore

TM

hot water system is now

complete. Follow the commissioning procedure carefully

to ensure the electric boosted solar hot water heating

system functions correctly.

Thermostats for electric boosted Stratco Solarcore

TM

hot

water heating systems are preset to 60°C in accordance

with plumbing regulations. A temperature limiting

device, such as thermostatic mixing or tempering valves,

must be fitted to limit the hot water temperature to 45°C

or 50°C where the hot water is supplied to areas used for

personal hygiene such as bathrooms and ensuites.

Please refer to AS/NZS3500.4 for temperature limits

for facilities such as child minding centres, schools and

nursing homes.

IMPORTANT NOTE

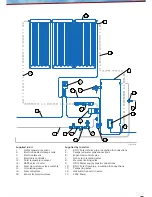

A hot water non-return valve must be fitted as shown in

Figures 29 & 30 to prevent hot water flowing to the cold

inlet of the tempering valve during stagnation conditions.

Failure to fit this non-return valve can result in excessive

tank noise or scalding when a hot tap is opened during

stagnation conditions.

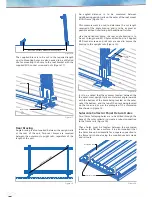

Installation Procedure

Position and install the solar collectors as outlined

in “Solar Collector Position & Orientation” of these

instructions.

Position and install the electronic controller as outlined in

“Installation of Electronic Controller” of these instructions.

Please refer to the manufacturer’s instructions for the

electronic controller installation and wiring connection

details. Failure to follow the manufacturer’s instructions

may cause failure of the electronic controller and will

void the warranty.

Position the hot water storage tank (and safe tray if

required) as outlined in “Installation of Electric Boosted

Storage Tank” of these instructions. Please refer to the

manufacturer’s instructions for the hot water storage tank

installation details. Failure to follow the manufacturer’s

instructions may cause failure of the hot water storage

tank and will void the warranty.

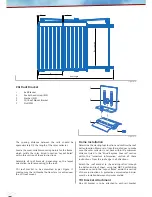

Fit the Pressure & Temperature Relief (P&TR) valve to

the connection marked “P&TR valve” near the top of the

tank as shown in Figure 30. Use Teflon thread tape and

ensure the tape does not protrude past the end of the

thread to prevent risk of valve blockage. Tighten the

P&TR valve using the spanner flats and leave the valve

outlet pointing down.

Fit the pressure limiting valve (where required), non-

return/isolating valve/strainer, expansion control valve

and pipe tee to the cold water inlet connection at the

bottom of the hot water storage tank. A pressure limiting

valve is required if the water supply pressure exceeds the

specifications for the hot water storage tanks in “Electric

Boosted Vitreous Enamel Storage Tank” .

Fit the solar collector flow pipe and insulation between

the cold water supply pipe tee and the water inlet of the

first solar collector. Fit the non-return valve and flow

regulator to the outlet of the circulation pump.