10mm (dia.) holes

Evacuated tubes

Figure 20

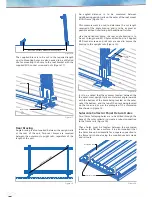

Angle brace

(rear)

Figure 19

Ang

led b

race leng

th

Figure 18

Side brace

M10 screw & nut

Figure 17

Measured distance between mounting slots

Figure 16

Solarcore Collector Panel Fixture Holes

Two 10mm fastening holes are to be drilled through the

base of the solar collector to create a robust connection

to the frame rails (Figure 20).

These holes must be located between the evacuated

tubes on the flat base surface. It is also important that

the holes line up horizontally for a square connection to

the frame rail channel using the supplied socket screws

and rail nuts.

Rear Bracing

Angle bracing is also required between the upright rails

at the rear of the unit. Two rear braces are required

between the outer-most upright rails, regardless of the

length of the unit.

An angled distance is to be measured between

neighbouring upright rails on the outer of the roof mount

tilt kit frame (Figure 18).

This measurement is used to determine the cut length

required of the angle bracing and is to be as great as

possible without interfering with additional fixtures.

Like the horizontal brace, the rear angle bracing is to

be cut to length and M10 holes drilled on site. Supplied

M10 socket screws and rail nuts are used to secure the

bracing to the upright rails (Figure 19).

It is to be noted that these braces located between the

the outer-most upright rails must always angle inwards

with the bottom of the brace being located on the outer

rail at the bottom, and the top of the brace being located

on the inner rail, as per the example of the dimension

line shown in Figure 18.

The supplied brace is to be cut to the required length

on site. Mounting holes are also needed to be drilled on

site for mounting the brace to the roof bracket with the

supplied M10 socket screw and nuts (Figure 17).