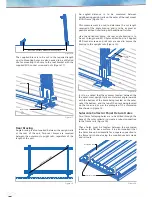

Upright rail

Tilt bracket

Second framing rail

Figure 15

Rail channel

M10 socket

screw & rail nut

combination

Figure 14

Loosen and adjust

screw heights to

determine ‘tilt’ angle

Figure 13

Rail bracket

Tilt bracket

Two M10 socket

screws & nuts

Figure 12

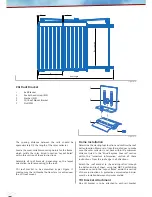

Side Bracing

Angle braces are to be attached to the roof bracket,

spanning between the front and rear roof brackets at

either end of the roof mount tilt kit unit for increased

stability.

The horizontal distance between the mounting holes on

the roof brackets is to be measured to gauge the length

required for the brace (Figure 16).

This process is to be replicated for each roof bracket,

with positioning reproduced accurately.

Position tilt brackets towards the top of the upright

rails using the supplied screws and rail nuts (Figure 15).

This must be completed on each upright rail. These tilt

brackets will support the second horizontal frame rail.

When the framing rail is supported by the upright rails

and tilt brackets, measure to be sure a consistent,

parallel distance between framing rails is found. Tighten

all mounting screws on the rails and roof brackets.

This can be assisted by fixing a brace between the first

and second frame rail at one end to stop the frame from

tipping, thereby keeping a square alignment.

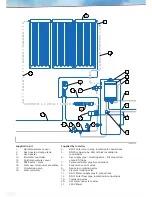

Upright Rail Positioning

Position a series of roof brackets corresponding to the

front row at the distance required to span the batten

distance.

Upright supports are to be cut to length from the supplied

frame rail with one upright required for each rear roof

bracket. Uprights are to be positioned in a manner that

allows for a channel facing towards the roof bracket, and

also facing outwards (Figure 14). Rail nuts and socket

screws are used to mount the upright to the roof bracket.

(Figure 12). This will allow the framing rail to attach in

the desired orientation. The tilt bracket angle will define

the tilt of the mount and is altered through positioning

adjustments to the M10 socket screws (Figure 13).

Replicate this process to create an even row of roof

brackets.

Attach the rail to the tilt brackets, using the supplied

screws and rail nut. The maximum overhang of the rail

from the roof bracket is 400mm. Attach a roof bracket

to the other end of the rail and slide into position, ready

for fastening.

Recheck the rail is parallel to the roof edge. Continue

installing the roof brackets and rails, as previously

described, while making sure that all subsequent rails are

square and parallel to the first rail. Tighten all mounting

screws on the rails and roof brackets.