-42-

For Machines Mfd. Since 12/21

South Bend Tools

Model SB1007

O P E R A T I O N

2.

Rotate high/low range switch to correct

setting for speed indicated on gear chart

(shown below): 1 (low) or 2 (high).

3.

Shift spindle speed levers to correct settings

for spindle speed range (see Figure 56).

Note:

If spindle speed levers do not easily

slide into position, rotate spindle by hand

while applying pressure to lever. When gears

align, lever will move easily into place. If you

have trouble rotating spindle by hand, use

spindle chuck key to get additional leverage.

Just be sure to remove key when you are

done.

4.

Reset STOP button. Start spindle rotation

using spindle direction switch.

Figure

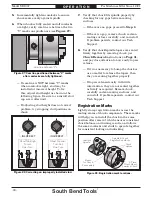

Figure 56. Spindle speed gear chart.

. Spindle speed gear chart.

1

2

600

410

110

300

200

55

1100

2200

Spindle Speed RPM

To avoid damaging spindle gears, ALWAYS

make sure spindle is completely stopped

BEFORE shifting spindle speed levers.

The spindle speed levers control the gear

configuration in the headstock, while the high/

low range switch determines high or low motor

speed.

To set spindle speed RPM:

1.

Press STOP button and make sure spindle

has completely stopped.

Additionally, the books Machinery's Handbook

or Machine Shop Practice, and some internet

sites, provide excellent recommendations for

which cutting speeds to use when calculating the

spindle speed. These sources provide a wealth

of additional information that will help you

take into account all the applicable variables in

order to determine the best spindle speed for the

operation.

Setting Spindle Speed

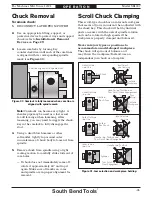

The spindle speed levers (see Figure 55) are

used in combination with the high/low range

switch to select any one of eight spindle speeds.

Figure

Figure 55. Spindle speed controls.

. Spindle speed controls.

Spindle

Spindle

Speed

Speed

Levers

Levers

High/Low

High/Low

Range Switch

Range Switch

Figure

Figure 54. Spindle speed chart for cutting common

. Spindle speed chart for cutting common

metals, taken from "How to Run a Lathe."

metals, taken from "How to Run a Lathe."

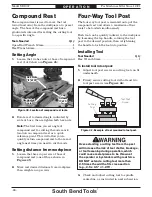

For your convenience, the table below provides a

set of pre-calculated spindle speeds for a variety

of workpiece sizes of different metal types. To

use this table, select the diameter that is closest

to your workpiece size, look across the row to the

number provided for your metal type, and then

set your spindle RPM at or near that number.

Содержание SB1007

Страница 84: ...southbendtools com Printed In U S A MN16349...