-40-

For Machines Mfd. Since 12/21

South Bend Tools

Model SB1007

O P E R A T I O N

Manual Feed

The handwheels shown in Figure 50 allow the

operator to manually move the cutting tool.

Carriage Handwheel

The carriage handwheel moves the carriage left

or right along the bed. It has a graduated dial

with 0.01" (0.2mm) increments, and one full

revolution moves the carriage 0.75" (19mm).

Cross Slide Handwheel

The cross slide handwheel moves the tool toward

and away from the work. Adjust the position of

the graduated scale by holding the handwheel

with one hand and turning the dial with the

other. The cross slide handwheel has a direct-

read graduated dial, which means that the dial

displays the amount removed from the workpiece

diameter (the slide only moves half the distance

shown on the dial). The dial has 0.002" (0.04mm)

increments, and one full revolution equals 0.16"

(4.0mm).

Compound Rest Handwheel

The compound rest handwheel moves the

cutting tool linearly along the set angle of the

compound rest. The compound rest angle is set

by hand-rotating it and securing it in place with

two hex nuts. The compound rest has a direct-

read graduated dial with 0.001" (0.025mm)

increments. One full revolution of the handwheel

moves the slide 0.50" (1.25mm).

Figure

Figure 50. Carriage handwheel controls.

. Carriage handwheel controls.

Compound

Compound

Rest

Rest

Handwheel

Handwheel

Carriage

Carriage

Handwheel

Handwheel

Cross Slide

Cross Slide

Handwheel

Handwheel

Carriage Stop

The carriage stop on this lathe is designed for

manually stopping the carriage at the same

position for repeat cuts. The carriage will NOT

automatically stop by itself when it contacts

the carriage stop.

The carriage stop allows you to manually stop

the carriage at the same position for repeat cuts,

such as when turning up to a shoulder. The

carriage stop includes an adjustable set screw

that allows you to precisely position the stop.

Tools Needed

Qty

Hex Wrench 4mm .................................................1

Hex Wrench 6mm .................................................1

Open-End Wrench 12mm .....................................1

To set carriage stop:

1.

DISCONNECT LATHE FROM POWER!

2.

Loosen the two cap screws shown in Figure

49, then use carriage handwheel to position

carriage at desired stopping point.

3.

Move carriage stop up to carriage and use

adjustable set screw to fine tune position.

4.

Retighten cap screws.

5.

Verify that tooling will not make contact

with chuck, jaws, or other components.

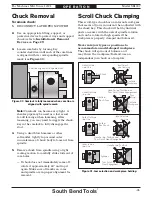

Figure

Figure 49. Location of carriage stop.

. Location of carriage stop.

Cap

Cap

Screws

Screws

Set Screw

Set Screw

Содержание SB1007

Страница 84: ...southbendtools com Printed In U S A MN16349...