75/238

Building Technologies

Modular Heating Controller RMH760B

CE1P3133en

HVAC Products

6 Boiler temperature control

05.02.2007

6.5.4

Control of modulating burners

Main menu > Commissioning > Settings > …

or

Main menu > Settings > Boiler > Burner modulating

Operating line

Range

Factory setting

Actuator run time

1…600 s

60 s

P-band Xp

1…200 K

20 K

Integral action time Tn

0…600 s

150 s

Derivative action time Tv

0…30 s

20 s

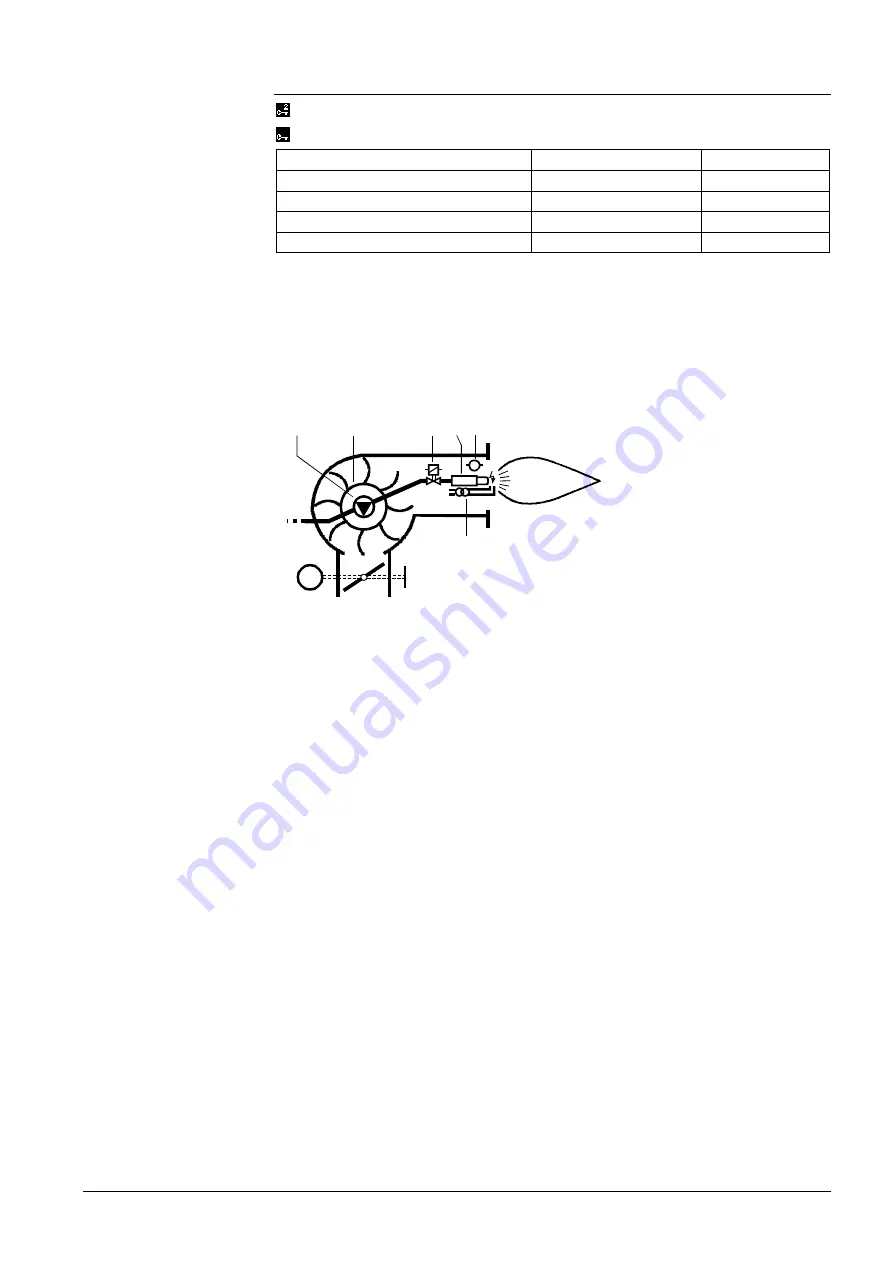

Modulating burners only modulate above a certain level. For standard forced draft

burners, this level is at about 30 to 40 % of the rated capacity.

When the demand for heat is small, the basic stage cycles. When the demand for heat

increases, the 3-position output or a DC 0…10 V output is used to control the combus-

tion air damper.

At the same time, the amount of fuel supplied will also be increased, typically via an

additional switch on the air damper, or by simultaneous control of the amount of fuel

(gas / air ratio).

25

26z

02

P

M

BV OH Q...

z

LK

SA

M

Basic design of a forced draft burner

BV Fuel

valve(s)

ACC Combustion air damper, fixed or motorized

M Fan

OH Oil preheater; located between nozzle and adjustable head with small light-oil burners, separate unit in the

case of large heavy-oil burners

P

Oil pump, coupled to fan motor

Q… Flame detector

SA Electromotoric air damper actuator

Z Ignition

transformer

The functioning with regard to activation and deactivation of the basic stage corre-

sponds to that of 2-stage burner operation. Release of modulation is analogous to the

release of the second stage.

The parameters used for the release and reset integral are the same as those used for

the 2-stage burner. Compared to the 2-stage burner, the release integral should be

selected smaller however (because in this case, it is not the entire capacity of stage 2

that is switched on, but only the modulating part that is released), and the reset integral

can be selected greater.

Release integral stage 2 or modulation: 10 K×m

Reset integral stage 2 or modulation

20 K×m

Locking time stage 2 or modulation

10 min

The locking time of stage 2 or modulation must be matched to the type of burner.

This ensures that the burner will always run in its basic stage for a minimum period of

time.

On burner startup and release of the basic stage, the controller drives the damper

actuator towards the fully closed position for a certain period of time. This ensures that,

after the burner startup sequence (prepurging, ignition, stabilization of flame, etc.), the

Recommended values for

modulating burners