á

•

Off: Limit value not active

•

Overflow (+): The limit value message is active when the measured value is

larger than the limit value.

•

Underflow (–): The limit value message is active when the measured value

is smaller than the limit value.

â

Hysteresis

ã

This flag is activated for the measured value (“-” in flag means no flag activa‐

tion) when the measured value is beyond the limit value.

ä

Programmed time limit value for an internal failure of the measuring signal or

the source value for this measured value.

å

Activated flag when the time limit value is overflown.

æ

Start value for using the measured value mask. Is also the output value in the

measured value mask range.

ç

Effective range of the measured value mask. Valid as from the start value; pos‐

itive or negative value possible.

è

Number of decimal places.

5.

Make the desired entries.

6.

Select

Save

.

6.6

Measuring points - automatic

6.6.1

Function of the measuring points automatic

Measuring point switchover

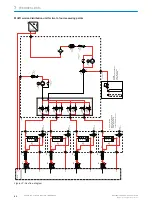

Measuring points are extraction points for sample gas. The “measuring points auto‐

matic” allows the BCU to control automatically up to 8 measuring points.

Hold function for analog outputs

When the measuring point automatic is activated for a measured value, the measured

values of the measuring points (MViMPj) are also provided internally as well as the

measured value (MVi). These measured values of the measuring points can be output

via the analog outputs. During the measuring time of the measuring point (

suring points - automatic", page 52

), the current measured value measured by MAR‐

SIC200 is output as measured value. During the remaining times, the last measured

value measured with this measuring point is output as a constant value.

NOTE

When the measuring point automatic is activated, an identifier of the current measuring

point is shown on the Measuring Screens and on the BCU display.

6.6.2

Criteria for measuring point automatic

•

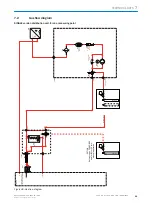

One digital output exists for each measuring point in the MARSIC200. The digital

output is configured for the measuring point (see “Technical Information BCU”).

•

A device is installed outside the MARSIC200 that switches the sample gas path to

the measuring point (e.g., a solenoid value). The associated digital output controls

this device.

•

At least two measuring points are configured and switched to “active” (

uring measuring point automatic", page 53

).

NOTE

Digital outputs for measuring points automatic are controlled using tag MPiS (see

“Technical Information BCU”).

6

TESTS AND SETTINGS

52

T E C H N I C A L I N F O R M A T I O N | MARSIC200

8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice