MX-M700N SIMULATION 7 – 47

4)

The input value is saved by pressing the [START] key

49

49-1

Purpose

Setting/update

Function (Purpose)

Firmware updating

Section

—

Operation/Procedure

1)

Before proceeding to the sim.49-1 screen, insert the USB

memory to the main unit.

* File and folder of the USB memory are displayed. (When the

foldername is longer than 34 characters, it is not completely

displayed.)

* If the USB memory is not inserted, "INSERT A USB MEM-

ORY DEVICE CONTAINING MFP FIRMWARE, PLEASE

USE FAT (12/16) FORMAT" is displayed.

* Non compliant to FAT32. If it's inserted, "CAN NOT SUP-

PORT FAT32. PLEASE USE FAT (12/16) FORMAT" is dis-

played.

2)

Enter the file/folder number of firmware that tries to be updated

with 10-key, and press [START] key.

3)

If selecting the file, "FIRMWARE UPDATE.. ARE YOU SURE

?" is displayed. ([1]: execute, [2]: get back)

* If the operation is normally completed, "COMPLEATE" is

displayed. When the error occurs, "ERROR" is displayed.

50

50-1

Purpose

Adjustment

Function (Purpose)

Used to adjust the copy image position and

the void area (image loss) adjustment on

print paper in the copy mode. (The similar

adjustment can be performed with SIM 50-

5 and 50-2 (Simplified method).) (Docu-

ment table mode)

Section

—

Operation/Procedure

(Leading edge image loss/void area adjustment)

1)

Set the adjustment values for leading edge image loss and

leading edge void as follows:

(Standard set value)

Lead edge image loss: 1.5mm (LEDA: 15)/Paper lead edge

void: 3.5mm (DENA: 35)

* Set LEAD to 15. (Enter 15 as the adjustment value of LEAD,

and press [P] key.) (0.1mm/step)

* Set DENA to 35. (Enter 35 as the adjustment value of

DENA, and press [P] key.) (0.1mm/step)

2)

Make a copy at the normal ratio (100%) and check the lead

edge void area and the image loss. (Enter 100 as the set value

of the copy magnification ratio (MAGNIFICATION), and press

[START] key.)

3)

If an acceptable result is not obtained, do the following steps.

* If the leading edge void area is not 3.5 mm:

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.) (1msec/step)

* If the lead edge image loss is not 1.5mm:

Change the adjustment value of RRCA and perform the

adjustment. (Change the adjustment value of RRCA and

press [START] key.)

(The adjustment value should be changed in steps of

0.2mm.)

(Trailing edge void area adjustment)

Adjust so that the rear edge void area is 3.5mm. (Change the

adjustment value of TRAIL EDGE, and press [START] key.)

(Front/rear frame direction image loss adjustment)

Set the (SIDE) adjustment value to 20 by entering "20" into the

(SIDE) adjustment value field and then pressing the [P] key.

Note that changing this adjustment value shifts the image position

in the front/rear frame direction.

(Front/rear frame direction void area)

Set the adjustment value of SIDE to 20. (Enter 20 as the adjust-

ment value of SIDE, and press [P] key.)

Adjust so that the total of the front/rear direction void areas is

7.0mm. (Change the adjustment values of FRONT/REAR, and

press [START] key.)

Front frame void area = 3.5mm Rear frame void area = 3.5mm

If, as shown above, the front and the rear void areas are not even,

use SIM 50-5 to adjust the image off-center position.

NOTE: When [P] key is pressed after entering an adjustment value

in this simulation, the adjustment value is set. When

[START] key is pressed, the adjustment value is set and

copying is performed.

0

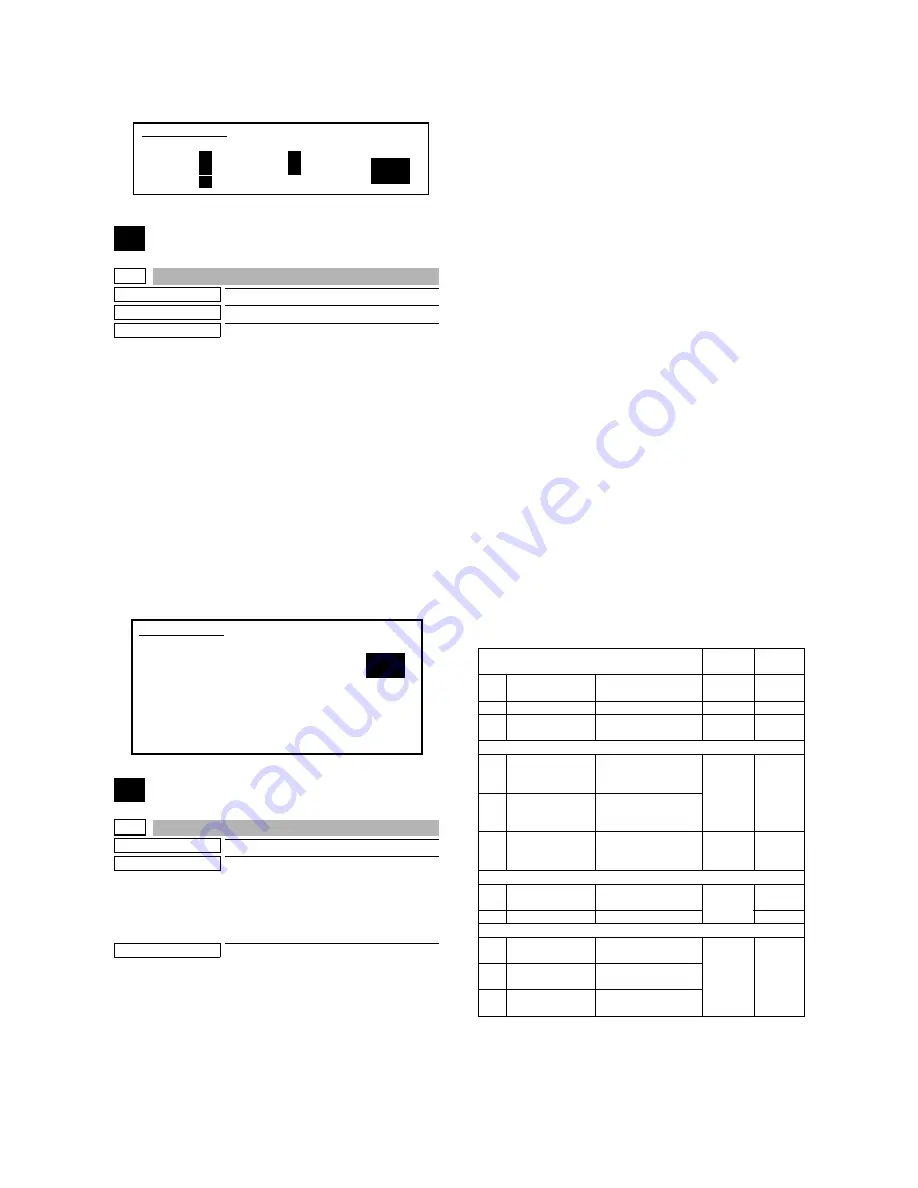

SIMULATION 48-5

MOTOR SPEED ADJUSTMENT. SELECT 0-4, AND PRESS START.

0.MIR(220)

50

1.MIR(110)

50

2.SPF(360)

50

3.SPF(220)

50

4.SPF(110)

50

SIMULATION 49-1

FIRMWARE UPDATE.

SELECT FIRMUP FILE, AND PRESS START.

1. FILE1.sfu

2. FILE2.sfu

3. FILE3.sfu

.

.

19. >>NEXT Page

0

Item

Setting

range

Default

0

TRAY SELECT

Paper feed tray

selection

1 - 6

-

1

COPY START

Copy START (Default)

-

-

2

MAGNIFICATION

Print magnification

ratio

25 -

400%

-

(Lead edge adjustment value)

3

RRCA

Document scan start

position adjustment

value

0 - 99

50

4

RRCB

Resist roller clutch ON

timing adjustment

value

10

SIDE2 ADJ.

Correction value for

RRCB in the back

surface print mode

1 - 99

50

(Image loss set value)

5

LEAD

LEAD Lead edge

image loss set value

0 - 99

15

6

SIDE

Side image loss set

20

(Void set value)

7

LEAD_EDGE

(DENA)

Lead edge void set

value

0 - 99

35

8

TRAIL_EDGE

(DENB)

Rear edge void

adjustment value

9

FRONT/REAR

Front/Rear void

adjustment value