10

Diagnosis levels

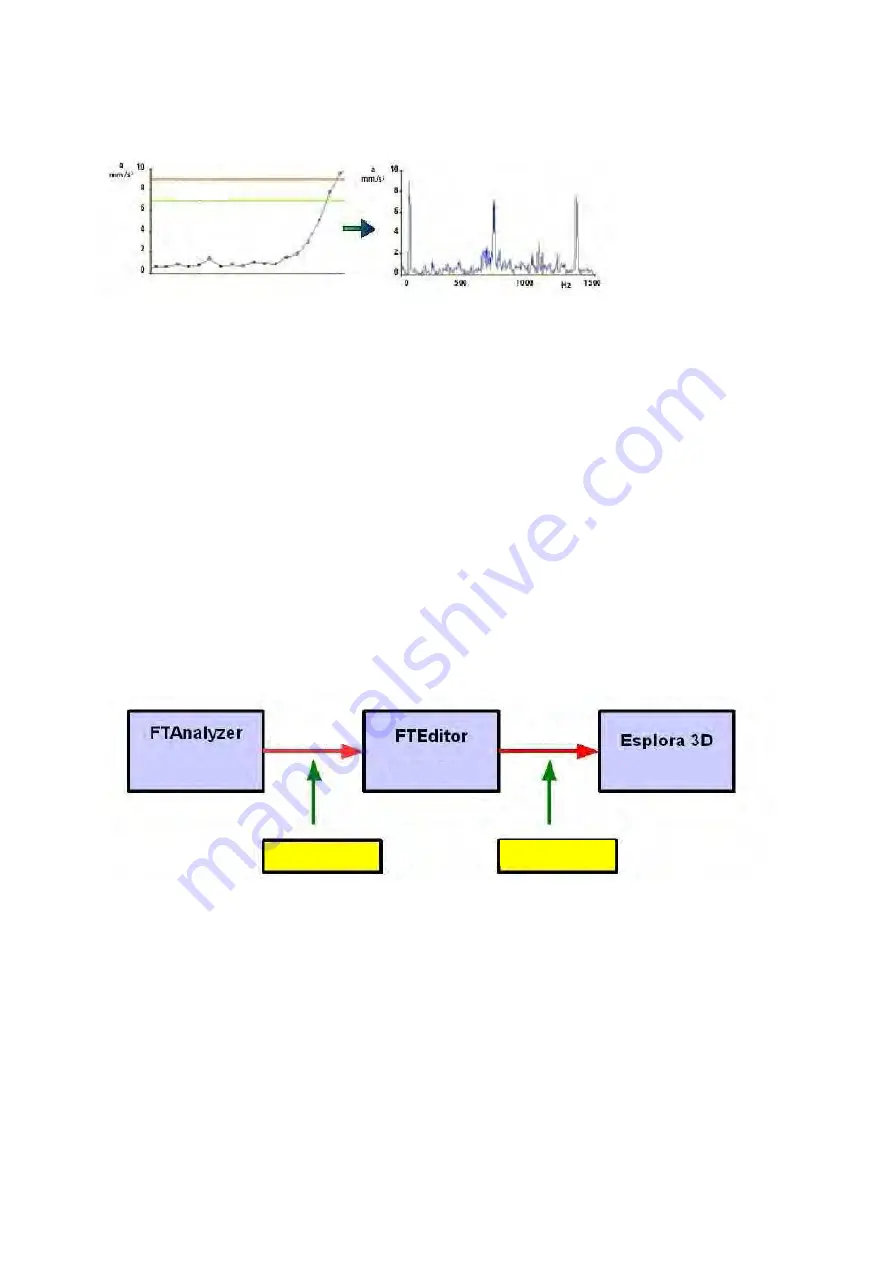

1.4 Philosophy of use

As above mentioned, the software provided with FastTracer are FTAnalyzer and Esplora 3D. With

the first, used to display and process measurement data, the user can analyse kinematic values such

as displacement, speed and acceleration in order to identify possible faults and establish their

effects. For example, to plan maintenance strategies for certain machine families, it is possible to

monitor a testing machine showing signs of a forthcoming fault and determine its effect on the

machine vibrational signature. After detecting the cause-effect relation, you can use the FTEditor

module of the FTAnalyzer to develop a test model dedicated to the concerned machine family. As

explained in chapter 5, this model can be used by less skilled users who, following the instructions

provided by the Esplora 3D software, will be led in the fault diagnosis function. The use of the

FastTracer for predictive maintenance reduces the number of inspections on the idle machine and

the number of stops due to unexpected faults, thus maximizing the maintenance efficiency and

effectiveness. Maintenance is simplified if you know in advance that a breakage or downtime is

approaching, as you can plan several aspects, such as personnel, spare parts and tools to be used,

thus saving costs and time.

How to use the software provided with FastTracer

threshold

Time

Vibration analysis

Experimentation

Test module

Specific tests

Cause-effect analysis

Standardized

diagnostics

Diagnostics dedicated to

the machine

2

nd

Level: Diagnosis

Component diagnosis

Occasional

measurement

1

st

Level: Monitoring

Overall machine

Long-term

Содержание FastTracer

Страница 2: ...Printed in February 2010...

Страница 53: ...53 Notes...