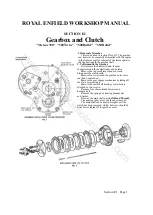

ROYAL ENFIELD WORKSHOP MANUAL

6. Removal of the Cylinder Head

"350 Bullet," "350 Clipper," "Works

Replica" and early "500 Bullet"

Remove the petrol tank (see Subsection 5).

Disconnect the engine steady.

Disconnect the plug lead and oil pipe.

Remove the exhaust pipe.

Push the carburettor back clear of the studs

after removing the fixing nuts.

Remove the rocker box covers.

Remove the decompressor cable from the

lever on the handlebar.

Turn the engine until both valves are closed.

Remove the rockers and bearings complete by

undoing four 1/4 in. nuts on each.

Lift out the push rods.

Remove six nuts, taking care not to lose the

washers.

Remove the 1/4 in. nut above the tappet chest

to avoid possible damage to the crankcase.

Lift the cylinder head off the barrel, tapping it

gently beneath the exhaust and inlet ports with a

hide hammer to break the carbon seal. Do not tap

the fins.

When fitting the head again, apply jointing

compound to both sides of the gasket, replace the

six nuts and tighten them progressively and

diagonally from one side to the other to prevent

distortion.

Replace the 1/4 in. nut above the timing

chest.

Replace the push rods with the adjustable parts

downwards, remembering that the shorter rod is

the inlet.

Replace the rockers and bearings, making sure

that the oil feed holes are at the bottom and that

the caps and bases are in line when tightened

down. A sharp tap with a hammer on the end of

the rocker will help to ensure this. See that the

valve stem caps are in place.

After the engine has been run long enough to

get thoroughly hot, the tightness of the nuts

should be rechecked.

It will be found convenient for this purpose

to use a small auxiliary petrol tank while the

engine is being warmed up on the stand, because

all the cylinder head nuts are not accessible with

the proper tank in position.

See that the rocker box gaskets are intact and

replace the rocker box covers.

After tightening the cylinder head nuts with

the engine hot, recheck the tappet clearance at

some convenient time when the engine is cold.

"500 Bullet," 1959 onwards

Remove the cylinder head steady bar, exhaust

pipe, carburettor, plug lead and the decompressor

cable at the handlebar end. Disconnect the rocker

oil feed pipes. Unscrew the five long nuts on the

top of the head, the nut adjacent to the sparking

plug and the sleeve nut by the decompressor.

Withdraw the five studs from the crankcase the

have squared ends to take a spanner.

Remove the rocker covers, rockers and push

rods. The rockers are removed by undoing the

nuts at either end; one of these nuts is bored and

tapped to take the oil union. Slide out the

spindle, taking care that the spring washer at the

push rod end and the plain washer at the other

end do not fall down the push rod tunnel.

Withdraw the push rods and lift the head.

For replacement reverse the order of the

above instructions. Make the joint between

cylinder head and barrel carefully as described in

Section C14 Page 4

the foregoing paragraph. Replace the push rods

and the five long studs in the crankcase,

tightening these very carefully. Replace all the

securing nuts, tightening them progressively to

avoid distortion.

Replace the rocker spindles, inserting them

through the box, through the spring washer held

at the push rod end, through the rocker and the

plain washer at the valve end and through the

other side of the rocker box. Put on the nuts, test

the rockers for freedom, replace the oil unions

and the rocker box covers. Deal with the sparking

plug, carburettor, exhaust pipe, decompressor

cable and head steady and so complete the

assembly.

7. Removal of the Valves

Remove the cylinder head and rockers (see

Subsection 6).

Prise away the hardened steel thimble or end

cap where fitted. If this has stuck it can be

removed by means of a screwdriver.

Using a suitable compressing tool, compress

the valve springs and remove the split conical

collets from the end of the valve stem.

Slacken back the compressing tool and release

the springs.

Withdraw the valve and place its springs, top

spring collar (and bottom collar if it is loose), the

end cap and split conical collets together in order

that they may be reassembled with the valve from

which they were removed.

Deal similarly with the other valve in the head.

If the valve will not slide easily through the valve

guide, remove any slight burrs on the end of the

valve stem with a carborundum stone. If the

burrs are not removed and the valve is forced out,

the guide may be damaged.

8. Removal of the Rockers

See Subsection 6.

9. Removal of the Valve Guides

To remove the valve guides from the head two

special tools are required which can easily be made.

The first is a piece of tube with an internal bore

of not less than 7/8 in.

The second is a mandrel about 4 in. long, made

from 9/16 in. diameter bar with the end turned

down to 11/32 in. diameter for 1/2 in.

Support the cylinder head on the tube which fits

over the collar of the valve guide. Using the

mandrel, force the guide out of the head with a hand

press or by using a hammer.

To fit a new guide, support the head at the correct

angle and use a hand press and the same mandrel. If

a hand press is not available and the guide is replaced

by a hammer, use the mandrel to prevent damage to

the guide.

It is necessary to recut the valve seat to the

correct profile and grind in the valve after a guide

has been replaced.

10. Removal of the Cylinder Barrel

Remove the Cylinder Head (see Subsection 6).

Put the piston at bottom dead centre.

Remove the 1/4 in. nut above the tappet chest

and lift the barrel off.

When replacing the cylinder barrel, clean off the

joint faces and fit a new paper washer.

11. Removal of the Piston

Remove the cylinder head and cylinder barrel (see

Subsections 6 and 10).

With the tang of a file remove the wire circlip

retaining the gudgeon pin on the timing side.

Extract the gudgeon pin using Special Tool No.

E.5477 (with adaptor if necessary), having first

marked the pin so that it, and the piston, may be

replaced the same way round, i.e. split skirt to the

front.

During this operation put a piece of clean rag in

the top of the crankcase to prevent foreign matter

getting in. In particular, take care not to drop the

circlip in the crankcase.

12. Decarbonising

Having removed the cylinder head as described in

Subsection 6, scrape away all carbon, with a suitable

tool, bearing in mind that you are dealing with

aluminium which is easily damaged. Scrape gently to

avoid scoring the combustion chamber or the valve

www.hitchcocksmotorcycles.com

Содержание 350 BULLET 1956

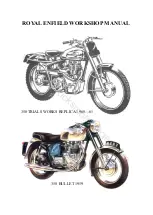

Страница 3: ...ROYAL ENFIELD WORKSHOP MANUAL 350 BULLET 1961 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 5: ...ROYAL ENFIELD WORKSHOP MANUAL 500 BULLET 1956 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 21: ...ROYAL ENFIELD WORKSHOP MANUAL 350 CLIPPER 1958 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 23: ...ROYAL ENFIELD WORKSHOP MANUAL Section E1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 28: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 30: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 42: ...ROYAL ENFIELD WORKSHOP MANUAL Section H5 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 71: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 72: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 73: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 4 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 74: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 75: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 6 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 76: ...ROYAL ENFIELD WORKSHOP MANUAL Section M4 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 79: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 80: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...