ROYAL ENFIELD WORKSHOP MANUAL

Section L12 Page 2

When replacing the wheel make sure that the

dogs on the speedometer drive gearbox are

engaged with the slots in the end of the hub

barrel. Make sure also that the speedometer drive

gearbox is correctly positioned so that there is no

sudden bend in the driving cable. Make sure that

the closed end of the spring link points in the

direction of travel of the chain. Replace the chain

adjuster cams in their original positions or, if

necessary, turn each of them the same number of

notches to tension the chain and maintain correct

wheel alignment. Do not forget to refit the brake

rod and adjust the brake so that the wheel turns

freely while the brake is off, while at the same

time only a small travel of the brake pedal is

necessary to put the brake on.

3. Removal of Brake Shoes for Replacement,

Fitting New Linings, etc.

Remove the complete wheel as described

above, then remove the left hand spindle nut,

chain adjuster and distance collar, thus permitting

the complete brake cover plate with operating

cam, pivot pin, shoes and return springs to be

lifted off the hub spindle.

In the case of the 7 in. brake fitted to the

"Meteor 700" and "500 Bullet" Models the brake

shoes can then be removed, after detaching the

return springs.

In the case of the 6 in. brake fitted to the "500

Twin" and "350 Bullet" Models, unscrew the

pivot pin locknut and the operating lever nut,

after which the assembly of the brake shoes,

return springs, pivot pin and operating cam can

be removed from the cover plate by unscrewing

the pivot pin and applying light blows with a

hammer and drift on the end of the operating

cam. The return springs can then be unhooked

from the spring posts in the brake shoes, thus

allowing the whole assembly to fall apart.

4. Replacing Brake Linings

Brake linings are supplied either in pairs ready

drilled complete with rivets, Part No. 37786BX (6

in. shoes) or 37787BX (7 in. shoes), or ready

fitted to service replacement brake shoes, Part

No. 38042 (6 in. shoes) or 38043 (7 in. shoes).

When riveting linings to shoes secure the two

centre rivets first so as to ensure that the lining

lies flat against the shoe. Standard linings are

Ferodo MR41 which are drilled to receive cheese

headed rivets.

5. Removal of Hub Spindle and Bearings

To remove the hub spindle and bearings,

having already removed the brake cover plate

assembly and speedometer drive gearbox, lift out

the felt washers and distance pieces then hit one

end of the spindle with a copper hammer or mallet

thus driving it out of the hub, bringing one bearing

with it and leaving the other in position in the hub.

Drive the bearing off the spindle and insert the

latter once more in the hub at the end from which

it was removed. Now drive the spindle through the

hub in the opposite direction, when it will bring

out the remaining bearing.

6. Hub Bearings

These are deep groove single row journal ball

bearings. The lighter bearings used in the "350

Bullet" and 500 Twin hubs are 5/8 in. i/d by

1.9/16 in. o/d by 7/16 in. wide. The Skefko Part

No. is RLS5. Equivalent bearings of other makes

are Hoffmann LS7, Ransome and Marles LJ 5/8

in., Fischer LS7.

The heavier bearings used in the "Meteor 700"

and "500 Bullet" Models are 5/8 in. i/d by

1.13/16 in. o/d by 5/8 in. wide. The Skefko Part

No. is RMS5. Equivalent bearings of other makes

are Hoffmann MS7, Ransome and Marles MJ 5/8

in., Fischer MS7.

7. Fitting Limits for Bearings

The fit of the bearings in the hub barrel is

important. The bearings are locked on the spindle

between shoulders and the distance pieces, which

in turn are held up by the cover plate nuts. In

order to prevent endways pre-loading of the

bearings it is essential that there is a small clearance

between the inner edge of the outer race of the

bearing and the back of the recess in either end of

the hub barrel. To prevent any possibility of

sideways movement of the hub barrel on the

bearings it is, therefore, necessary for the bearings

to be a tight fit in the barrel but this fit must not be

so tight as to close down the outer race of the

bearing and thus overload the balls. The following

are the manufacturing tolerances which control the

fit of the bearings. The figures for the bearings

themselves are for SKF bearings but other

manufacturers tolerances are similar.

350 Bullet Meteor 700

and 500 Twin and 500Bullet

Bearing o/d 1.5622/1.5617 in. 1.8122/1.8117 in.

Housing bore 1.5620/1.5615 in. 1.8115/1.8110 in.

Bearing bore .6252/.6247 in. .6252/.6247 in.

Shaft diameter .6252/.6248 in. .6252/.6248 in.

8. Refitting Ball Bearings

Note that the two ends of the spindle are not

identical. The end with the shorter plain portion

between the thread and the shoulder must be fitted

to the brake drum side of the wheel.

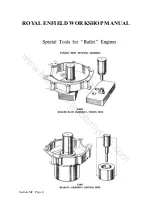

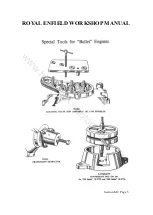

To refit the bearings in the hub two hollow

drifts are required, as shown in Figs. 2 and 3. One

bearing is first fitted to one end of the spindle by

means of the hollow drift; the spindle and bearing

www.hitchcocksmotorcycles.com

Содержание 350 BULLET 1956

Страница 3: ...ROYAL ENFIELD WORKSHOP MANUAL 350 BULLET 1961 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 5: ...ROYAL ENFIELD WORKSHOP MANUAL 500 BULLET 1956 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 21: ...ROYAL ENFIELD WORKSHOP MANUAL 350 CLIPPER 1958 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 23: ...ROYAL ENFIELD WORKSHOP MANUAL Section E1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 28: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 30: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 42: ...ROYAL ENFIELD WORKSHOP MANUAL Section H5 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 71: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 72: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 73: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 4 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 74: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 75: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 6 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 76: ...ROYAL ENFIELD WORKSHOP MANUAL Section M4 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 79: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 80: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...