ROYAL ENFIELD WORKSHOP MANUAL

Section C14 Page 5

seats, which are of austenitic iron shrunk into the

head. Be careful not to injure the joint face which

beds down on to the head gasket.

Do not, in any circumstances, use caustic soda

or potash for the removal of carbon from

aluminium alloy.

Scrape away all carbon from the valve heads

and beneath the heads, being careful not to cause

any damage to the valve faces.

If the piston rings are removed, the grooves

can be cleaned out and new ones fitted. For

cleaning the grooves a suitable tool is a piece of

broken ring thrust into a wooden handle and filed

to a chisel point.

While the cylinder and piston are not in

position, cover the crankcase with a clean cloth to

prevent the ingress of dust and dirt of all kinds.

Do not, of course, attempt to scrape the carbon

from the piston when the mouth of the crankcase

is open.

13. Grinding in the Valves

To grind a valve, smear the seating with a little

grinding-in compound, place a light, short coil

spring over the valve stem and beneath the head,

insert the valve into its appropriate guide, press it

on to the seat using a tool with a suction cup and

with a backwards and forwards rotary motion,

grind it on to its seat. Alternatively, a tool which

pulls on the valve stem can be used. Frequently lift

the valve and move it round so that an even and

true seating is obtained. If no light spring is

available, the lifting will have to be done by hand.

Continue grinding until a bright ring is visible on

both valve and seating.

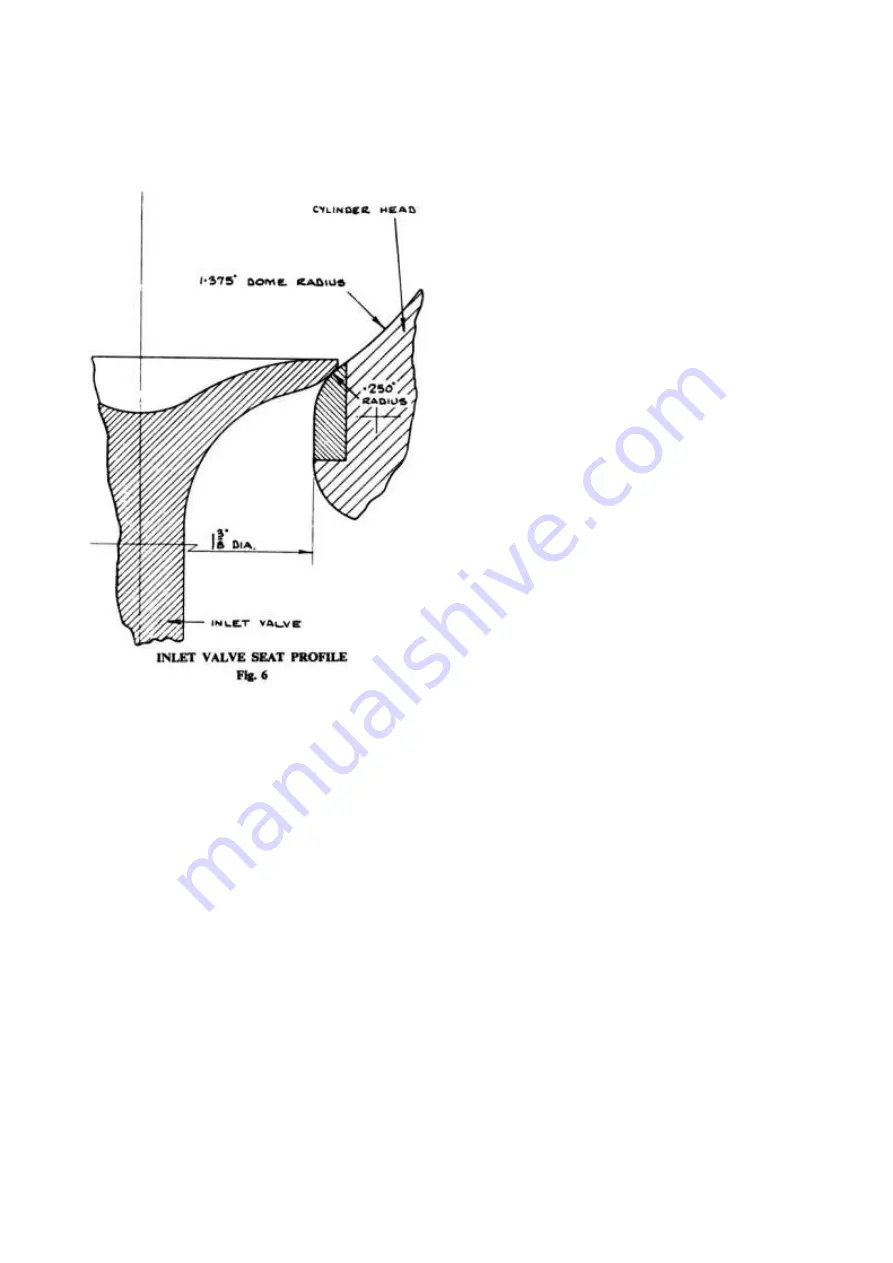

The face and seat of the exhaust valve is cut at

45 degrees but the profile of the inlet valve is of a

special streamlined design which eliminates

pockets and sharp edges and allows a smooth flow

of gas without eddies.

If the inlet valve or its seat is pitted and

requires recutting, care must be taken to reproduce

the correct profile as shown in Fig. 6.

The cylinder head should preferably be returned

to the Works for the inlet valve seat to be recut,

but if this is not possible a special tool consisting of

an arbor and cutter is available. For the "350

Bullet" the arbor and cutter are No. T.2053 and

T.1891; for the "500 Bullet," T.2053 and T.1892.

Great care must be exercised in using, this tool, as

it is located off the valve guide and this may be

damaged if suitable apparatus is not employed.

The inlet valve face and seat can be cut at 45

degrees in case of expediency but this may have a

deleterious effect on the performance of the

engine.

14. Reassembly after Decarbonising

Before building up the engine, see that all parts

are scrupulously clean and place them

conveniently to hand on a clean sheet of brown

paper.

When reassembling the engine, it is advisable to

fit a new paper washer between the cylinder barrel

and the crankcase.

Smear clean oil over the piston and space the

ring gaps, having replaced the rings if these have

been removed. The taper ring is marked "TOP" on

the upper face. Lower the piston over the

connecting rod and insert the gudgeon pin. Fit the

circlip securing the gudgeon pin.

If the piston ring gaps exceed 1/16 in. when the

rings are in position in the barrel, new rings should

be fitted. The correct gap for new rings is .011 in. -

015 in. The gap should be measured in the least

worn part of the cylinder, which will be found to

be the extreme top or bottom of the bore.

Oil the cylinder bore and lower the barrel over

the piston and seat it gently on the paper washer.

Tighten down the nut above the tappet chest and

replace the cylinder head and rockers as described

in Subsection 4.

www.hitchcocksmotorcycles.com

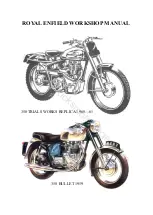

Содержание 350 BULLET 1956

Страница 3: ...ROYAL ENFIELD WORKSHOP MANUAL 350 BULLET 1961 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 5: ...ROYAL ENFIELD WORKSHOP MANUAL 500 BULLET 1956 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 21: ...ROYAL ENFIELD WORKSHOP MANUAL 350 CLIPPER 1958 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 23: ...ROYAL ENFIELD WORKSHOP MANUAL Section E1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 28: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 30: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 42: ...ROYAL ENFIELD WORKSHOP MANUAL Section H5 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 71: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 72: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 73: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 4 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 74: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 75: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 6 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 76: ...ROYAL ENFIELD WORKSHOP MANUAL Section M4 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 79: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 80: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...