ROYAL ENFIELD WORKSHOP MANUAL

Section C14 Page 7

Check the pump disc springs for fatigue by

assembling in the timing cover and placing the

pump covers in position. The latter should be held

1/8 in. off the timing cover if the springs are

correct.

In the case of the 500 c.c. engine see that the

steel end pads are in position on the outer ends of

the springs.

The pump spindle should be renewed if

excessive wear has taken place on the teeth.

Reassemble the oil pumps, replacing the paper

cover gaskets if necessary. Before fitting each

cover fill the pump chamber with clean oil.

Having assembled the pumps, lay the timing

cover flat and fill the oil ports by means of an oil

can. Turn the pump spindle with a screwdriver in

a clockwise direction looking on the front and it

can then be seen whether the pumps are operating

correctly.

Before replacing the timing cover on the

engine, fill the filter chamber with clean oil.

The oil feed to the big end can be checked by

partially unscrewing the feed plug in the timing

cover between the oil pumps while the engine is

running and the oil return to the tank can be

checked by removing the oil filler cap.

17. Removal of Pump Worm and Timing

Pinion

Remove the timing cover as described in

Subsection 1.

Unscrew the worm shaft by a hexagon head

behind the worm, using Special Tool No. E.5451.

This is a left-hand thread.

Withdraw the timing pinion by means of a flat

chisel placed behind the pinion and tapped gently.

When refitting the timing cover see that the

cork or rubber plug is in position in the hole in

the pump worm and is undamaged.

18. Removal of the Magneto or Contact

Breaker Pinion Unit

After first removing the timing cover of an

engine having magneto ignition, the pinion of the

type which incorporates an auto-advance unit is

removed by unscrewing the centre nut. This will

draw the pinion and auto-advance unit of the

shaft.

Coil ignition models: The auto-advance

mechanism in this case is in the contact breaker

unit, and the pinion is drawn off by removing the

securing nut and operating the extractor tool.

The "Works Replica," which employs

magneto ignition, but no auto-advance

mechanism, also follows this procedure.

19. Primary Chain Adjustment

Access to the primary chain adjuster is gained

by removing the primary chain cover, which is

To take up slack in the primary chain, unscrew the

locknut and turn the adjuster beneath the curved slipper

until correct chain tension is obtained; retighten the

locknut.

held in position by a single nut. Before removing the

nut, place a tray under the engine to catch the oil

from the chaincase.

Beneath the bottom run of the chain is a curved

slipper on which the chain rests and which may be

raised or lowered by turning the adjusting screw after

having first slackened the locknut.

The chain should be adjusted so that there: is ¼ in.

up and down movement at the centre of the top run

of the chain.

After replacing the chain cover remember to

replenish the chaincase with oil.

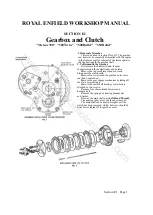

20. Removal of the Engine and Clutch Sprockets

The primary chain is endless so that it is

necessary to remove both the engine and clutch

sprockets simultaneously.

Remove the alternator stator by undoing three

fixing screws.

Remove the central hexagon nut securing the

alternator rotor, which can then be drawn off, taking

care not to lose the key.

Unscrew the engine sprocket nut using Special

fool No. E.4877. The engine sprocket is mounted on

splines and can then be removed with the clutch

sprocket.

To remove the clutch sprocket unscrew tile

clutch spring pins then lift away the spring cap,

springs and distance pieces, clutch front plate, centre

www.hitchcocksmotorcycles.com

Содержание 350 BULLET 1956

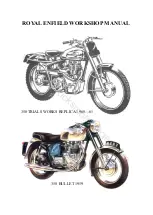

Страница 3: ...ROYAL ENFIELD WORKSHOP MANUAL 350 BULLET 1961 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 5: ...ROYAL ENFIELD WORKSHOP MANUAL 500 BULLET 1956 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

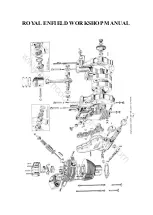

Страница 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 21: ...ROYAL ENFIELD WORKSHOP MANUAL 350 CLIPPER 1958 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 23: ...ROYAL ENFIELD WORKSHOP MANUAL Section E1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 28: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 30: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 42: ...ROYAL ENFIELD WORKSHOP MANUAL Section H5 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 71: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 72: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 73: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 4 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 74: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 75: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 6 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 76: ...ROYAL ENFIELD WORKSHOP MANUAL Section M4 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 79: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 80: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...