ROYAL ENFIELD WORKSHOP MANUAL

Section K7 Page 3

on the circumference of the rim shoulders where

the tyre fits being 53.642/53.582 in. The standard

steel measuring tape for checking rims is 5/16 in.

wide, .011 in. thick, and its length is 53.676/

53.616 in.

Up to 1959 "Clipper," up to 1962 "500 Bullet,"

up to 1958 "350 Bullet": The wheel rim is

WM2-19 in. plunged and pierced with forty holes

for spoke nipples. The spokes are symmetrical, i.e.

the rim can be assembled either way round. The

rim diameter after building is 19.062 in., the

tolerances on the circumference of the rim

shoulders where the tyre fits being 59.930/59.870

in. The standard steel measuring tape for checking

rims is 5/16 in. wide, .011 in. thick and its length

is 59.964/59.904 in.

12. Spokes

"350 Clipper," 1960: The spokes are of the

singlebutted type, 8-10 gauge, with 90°

countersunk heads, thread diameter .144 in., 40

threads per inch, thread form British Standard

Cycle. The inner spokes are 5.5/8 in. long with an

angle of bend 100', and the outer spokes 5.3/4 in.

long with an angle of bend 80°.

The "Trials" model has a 6 in. brake, the front

rim is WM1-21 in., there are forty spokes 7.9/16

in. long 10-8 gauge. On all "350 Bullets" up to

1958, "Clippers" up to 1959 and "500 Bullets" up

to 1962, the inner and outer spokes are 6.5/8 in.

long. "350 Bullets," 1959 to 1962 have spokes

6.5/16 in. long.

13. Wheel Building and Truing

The spokes are laced one over two, and the

wheel rim must be built central in relation to the

faces of the nuts on the spindle. The rim should

be trued as accurately as possible, the maximum

permissible run-out both sideways and radially

being plus or minus 1/32 in.

14. Tyre

The standard tyre is Dunlop 3.25-17 in.

Ribbed. "350 Bullet" up to 1958. "350 Clipper"

up to 1959, "500 Bullet" up to 1962: use a 3.25-19

in. When removing the tyre always start close to

the valve and see that the edge of the cover at the

other side of the wheel is pushed down into the

well in the rim.

When replacing the tyre fit the part by the

valve last, also with the edge of the cover at the

other side of the wheel pushed down into the

well.

If the correct method of fitting and removal of

the tyre is adopted it will be found that the covers

can be manipulated quite easily with the small

levers supplied in the tool-kit. The use of long

levers and/or excessive force is liable to damage

the walls of the tyre. After inflation, make sure

that the tyre is fitting evenly all the way round the

rim. A line moulded on the wall of the tyre

indicates whether or not the tyre is correctly fitted.

If the tyre has a white mark indicating, a balance

point, this should be fitted near the valve.

15. Tyre Pressures

The recommended pressures for the front

tyres are 16 lb. per square inch for wheel loads

not exceeding 200 lb., 18 lb. per square inch for

load up to 240 lb., 20 lb. per square inch for loads

up to 280 lb., and 24 lb. per square inch up to 350

lb.

16. Lubrication

Grease the bearings by packing them with

grease after dismantling the hub as described

above.

Note that the brake cam is drilled for a grease

passage but the end of this is stopped up with a

countersunk screw instead of being fitted with a

grease nipple. This is done to present excessive

greasing by over-enthusiastic owners. If the cam is

smeared with grease on assembly it should require

no further attention but in case of necessity, it is

possible to remove the screw, fit a grease nipple in

its place and grease the cam by this means.

www.hitchcocksmotorcycles.com

Содержание 350 BULLET 1956

Страница 3: ...ROYAL ENFIELD WORKSHOP MANUAL 350 BULLET 1961 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 5: ...ROYAL ENFIELD WORKSHOP MANUAL 500 BULLET 1956 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 21: ...ROYAL ENFIELD WORKSHOP MANUAL 350 CLIPPER 1958 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 23: ...ROYAL ENFIELD WORKSHOP MANUAL Section E1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 28: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 30: ...ROYAL ENFIELD WORKSHOP MANUAL Section F4 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

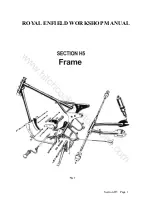

Страница 42: ...ROYAL ENFIELD WORKSHOP MANUAL Section H5 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 71: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 72: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 73: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 4 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 74: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 5 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 75: ...ROYAL ENFIELD WORKSHOP MANUAL Section M2 Page 6 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 76: ...ROYAL ENFIELD WORKSHOP MANUAL Section M4 Page 1 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 79: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 2 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Страница 80: ...ROYAL ENFIELD WORKSHOP MANUAL Section P1 Page 3 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...