4-28

16

15

1

2

3

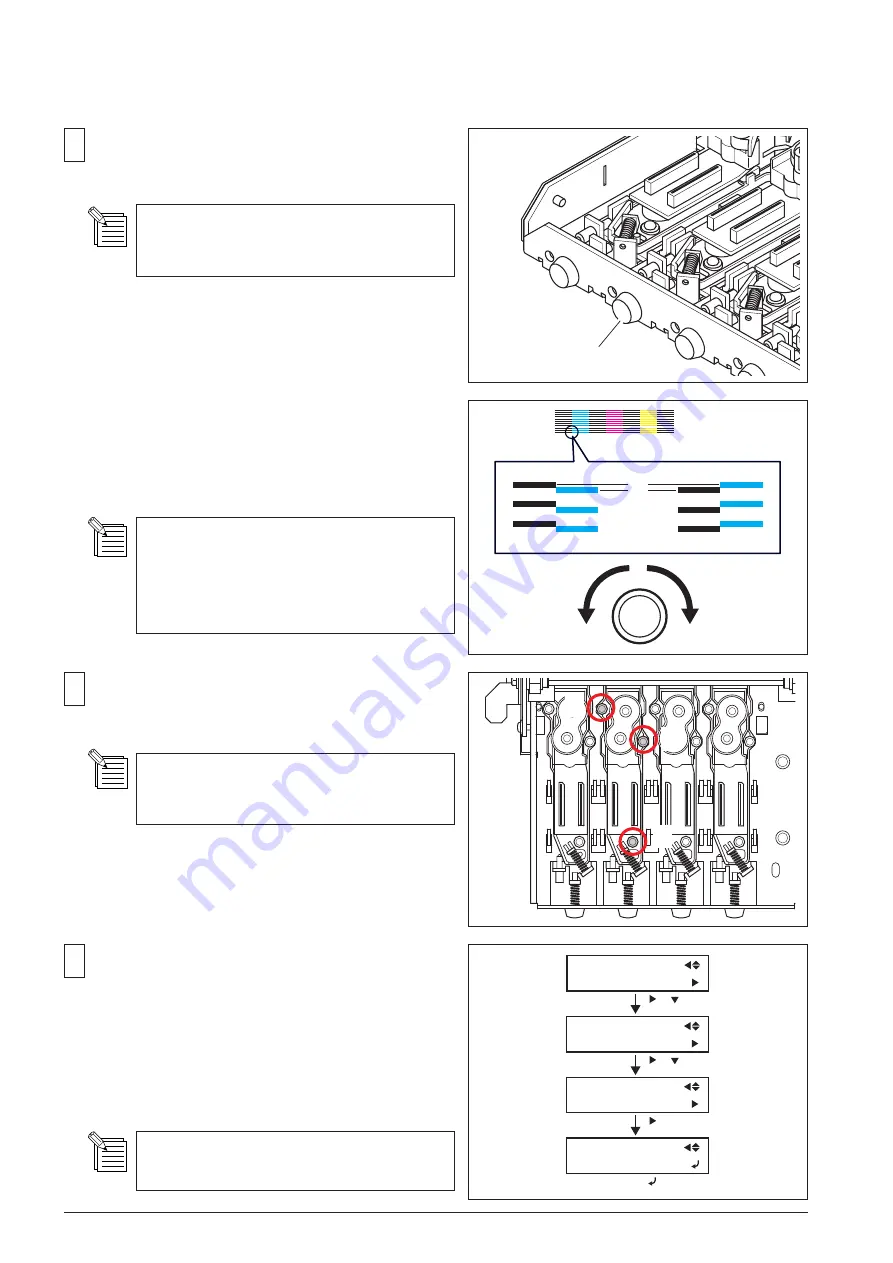

When the lines other than K are above the K lines, turn

the Adjustment Screw CW.

When the lines other than K are below the K lines, turn

the Adjustment Screw CCW.

Adjust the head positions referring to the left-

end K head as the base position. The position

of K head on the left end does not need to be

adjusted.

Tighten the screws fixing the head in order as shown in

the figure, using the Torque Driver (ST-056).

Torque for tightening is

2kgf • cm (20cNm)

.

Make sure not to tighten the screws too strong.

Print the test pattern again.

If the result is not satisfactory, repeat step 11 to 15.

If the VERTICAL test print reult is satisfactory, select

[HEAD ADJUST]> [BIAS]> [TEST PRINT], and print the

BIAS test pattern again.

If the BIAS test print result is not satisfactory, repeat

BIAS ADJUSTMENT.

The shifting of lines should be smaller than 1/2

dot.

14

Turn the Adjustment Screw to make the lines of each color

in the test pattern straight.

ADJUSTMENT SCREW

[ ]

PRINT MENU

HEAD ADJUST

HEAD ADJUST

BIAS

BIAS

TEST PRINT

[ ]

[ ]

SERVICE MENU

PRINT MENU

[ ] [ ]

[ ]

Position of the printing moves 1 line by turning

the screw 1/6 turn.

Содержание VersaCamm VP-300

Страница 39: ...2 4 2 MAIN BOARD_Arrangement Diagram Soldering Side ...

Страница 50: ...2 15 2 SERVO BOARD_Arrangement Diagram Soldering Side ...

Страница 58: ...2 23 2 2 5 SUB BOARD It indicates the version of the Board SUB BOARD_Arrangement Diagram Component Side ...

Страница 102: ...3 39 Move the Head Carriage by hand to the lock position HEADCARRIAGE Fix the I S Cover SCREW I SCOVER HOOK 20 21 ...

Страница 222: ...7 2 7 Unpacking Manual etc CD ROM etc ...