Chapter 6 What to Do If

151

Chapter 6 What to Do If

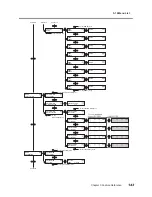

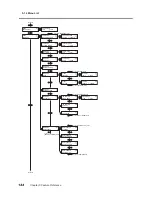

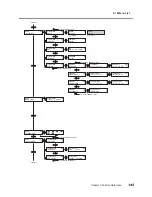

Printed Results Are Coarse or Contain Horizontal Stripes

Do the print heads show dot drop-out?

Carry out a printing test and make sure no dot drop-

out occurs. If dot drop-out is present, perform head

cleaning.

P. 45, "Printing Tests and Cleaning"

P. 67, "When Head Cleaning Is Not Effective"

P. 84, "Adjustment of White Ink"

Is the head height appropriate?

Printing when the [HEAD HEIGHT] menu item is set

to "HIGH" is coarser than when set to "LOW." Keep this

set to "LOW" except when changing it is necessary,

such as when you're using thick media.

P. 106, "Adjusting Head Height to Match Media Thick-

ness"

Have you carried out feed correction?

Large misalignment in the amount of feed of the

media may result in printing that seems coarse or con-

tains horizontal stripes. Either make the setting on the

computer to match the type of media you're using, or

make the setting for correction on the printer.

P. 111, "Performing Feed Correction to Alleviate Horizontal

Bands and the Like"

Did the media become slack during feed

correction?

Slackness of the media during feed correction makes

accurate correction impossible. Carry out feed correc-

tion with the media pulled taut.

P. 111, "Performing Feed Correction to Alleviate Horizontal

Bands and the Like"

After feed correction, was the media pulled

back?

Never pull the media back after carrying out feed

correction. Doing so may cause the correction results

not to be applied properly and result in horizontal

stripes.

P. 111, "Performing Feed Correction to Alleviate Horizontal

Bands and the Like"

Have you carried out bidirectional correc-

tion?

When you are performing bidirectional printing,

use the [ADJUST BI-DIR] menu item to carry out

correction. The optimal adjustment value may vary,

depending mainly on the thickness of the media.

Set or select an adjustment value that is suited to

the media.

P. 107, "Correcting for Misalignment in Bidirectional

Printing"

P. 108, "Correcting for Misalignment in Bidirectional

Printing More Precisely"

Is the print mode suitable?

Try a higher-quality print mode. Depending on the

media, uneven colors may occur in high-quality print

modes, and the results are also greatly affected by

the settings of the software RIP (such as the selected

color profile). Make settings suited to the media

you're using.

Is the printer installed in a level and stable

location?

Never install the machine in a location where it is

tilted or where it may wobble or experience vibration.

Also make sure that the print heads are not exposed

to moving air. These factors may lead to missing dots

or reduced printing quality.

Is the printer installed in a location out of

direct sunlight?

Never install in a location exposed to direct sunlight.

Doing so may result in dot drop-out or other prob-

lems with reduced printing quality, or may even result

in malfunction.

Is the media loaded and set up correctly?

If the media is not loaded and set up correctly,

media feed may not be smooth, or printing may be

adversely affected.

P. 156, "Media Wrinkles or Shrinks, or Feed Is Unstable"

Are the settings for the [PRESET] menu item

appropriate?

If the settings selected with the [PRESET] menu item

are not suitable for the type of media, printing may

be adversely affected. Choose settings optimized to

the media you're using.

6-2 Attractive Printing Is Impossible

Содержание LEC-300A

Страница 24: ...22 ...

Страница 25: ...Chapter 1 Introduction 23 ...

Страница 32: ...30 ...

Страница 33: ...Chapter 2 Basic Operation 31 ...

Страница 56: ...54 ...

Страница 57: ...Chapter 3 Operation of the Me dia Take up System 55 ...

Страница 65: ...Chapter 4 Maintenance and Adjustment 63 ...

Страница 91: ...Chapter 5 Feature Reference 89 ...

Страница 151: ...Chapter 6 What to Do If 149 ...

Страница 164: ...162 ...

Страница 165: ...Chapter 7 Specifications 163 ...

Страница 173: ...171 ...

Страница 174: ...172 ...

Страница 175: ...173 ...

Страница 176: ...174 ...

Страница 177: ...175 ...

Страница 178: ...176 ...

Страница 179: ......

Страница 180: ...R1 091026 ...