Saving Data

Save the data you have created to a hard disk or the like.

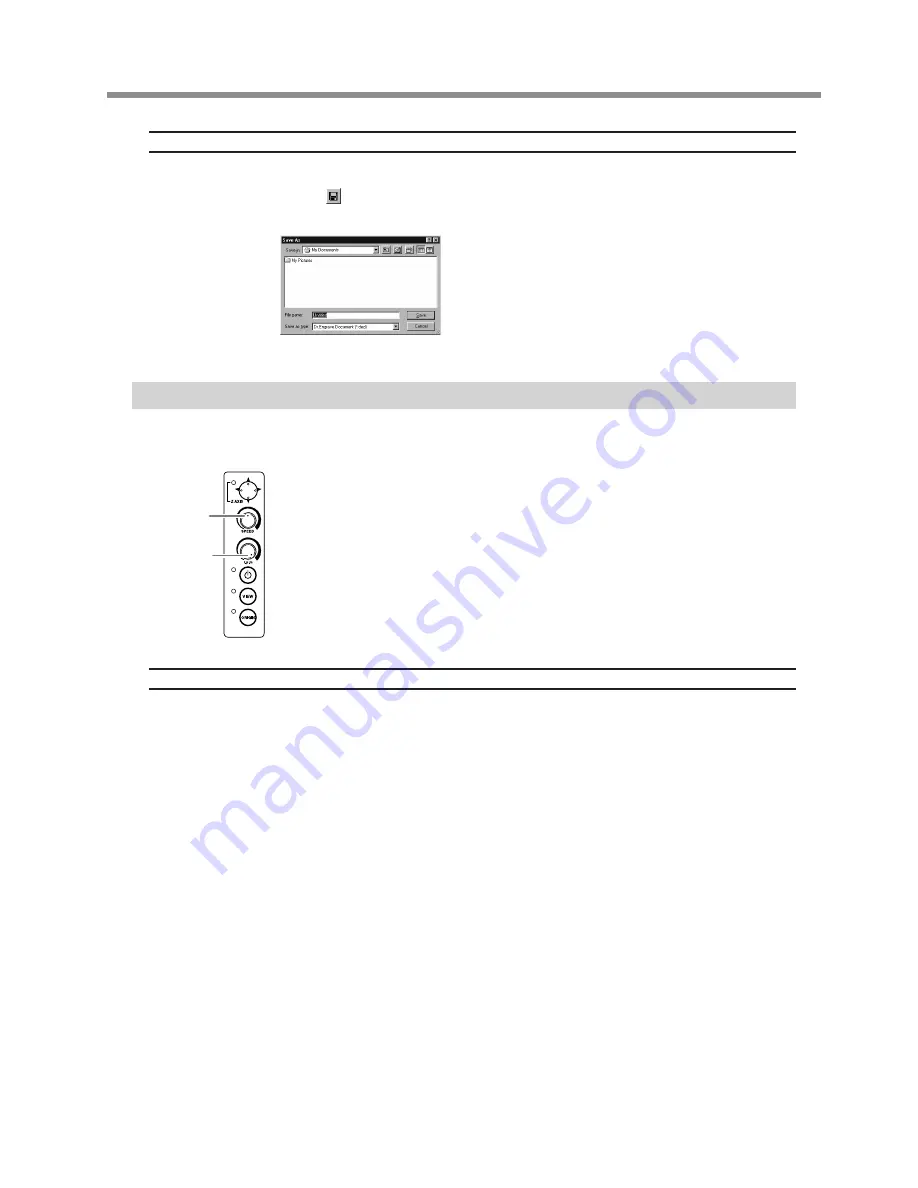

At the toolbar, click . Alternatively, go to the [File] menu and select [Save As].

The [Save As] dialog box appears.

Specify the information for [Save in]

and [File Name], then click [Save].

Setting the Cutting Parameters

Before you carry out engraving, adjust the Speed control and Spindle Speed control on the switch panel of the EGX-20.

When you're performing engraving for the first time, set the Speed control at the

central position and the Spindle Speed control at its maximum setting.

Also, if you're using acrylic material and the included blade, then you may leave the

settings for the EGX-20 driver at their default values.

Go ahead and try engraving using these settings.

In some cases it may not be possible to perform engraving smoothly. In such cases, ex-

amine the engraving results and adjust the settings for the cutting parameters, repeat-

ing this process of trial and adjustment until you obtain good engraving results.

General Suggestions for Making Adjustments

Depending on the engraving results, make the settings as described below. Use the Speed control and the Spindle Speed

control to make the adjustments.

• If engraved places are rough (not smooth), then lower the speed.

• If the material melts or suffers burring, lower the spindle speed.

• If the spindle speed is too fast, the material may melt. Lower the spindle speed. Also, if there is buildup of melted cuttings

in engraved grooves, you may be able to remove them by scrubbing with a toothbrush or the like.

• Increasing the spindle speed when using a narrower blade and reducing it when using a thicker blade may produce

better results.

• In many cases, slower speeds produce attractive finished results, but a speed that is too slow may cause melting.

Make the following adjustments with the driver.

• The default engraving depth is 0.1 mm. You can engrave at a greater depth by changing the value for the driver setting [Z

Down Position]. The maximum depth at which you can engrave is 1.0 mm. (In the driver, you make the setting by specify-

ing a value prefixed by a minus sign ["-"].) A greater engraving depth yields correspondingly wider lines. This means that

text characters also become thicker.

• If the engraving depth is too deep, it may not be possible to obtain attractive results even when the speed and spindle

speed are adjusted.

• One method for obtaining engraving results that are attractive yet deep is to perform the same engraving twice. (For

example, setting [Z Down Position] to -0.18 mm and [Z Cutting Pitch] to 0.10 mm results in engraving in two passes, to

a depth of 0.18 mm. )

• Leave [Z Up Position] set to 0.50 mm at all times. Lower values result in less wasted movement.

•

You can obtain attractive engraving results by setting [Fill Pitch] to 80% or less than the width of the cutter -- actually at about

50%.

P. 23, "Filling a Text String"

At the central

position

At maximum

25

3 Creating a Nameplate (Engraving Mode)

Содержание EGX-20

Страница 51: ......