9

RealCareer® Welding Solutions – guideWELD® LIVE real welding guidance system

Calibration Process

NOTICE:

The calibration process will need to be

completed before each weld!

The process includes Speed Sensor alignment and Angle Sensor calibration. The process is

the same for Stick or MIG welding except when of using the Stick Calibration Fixture (for Stick

welding only).

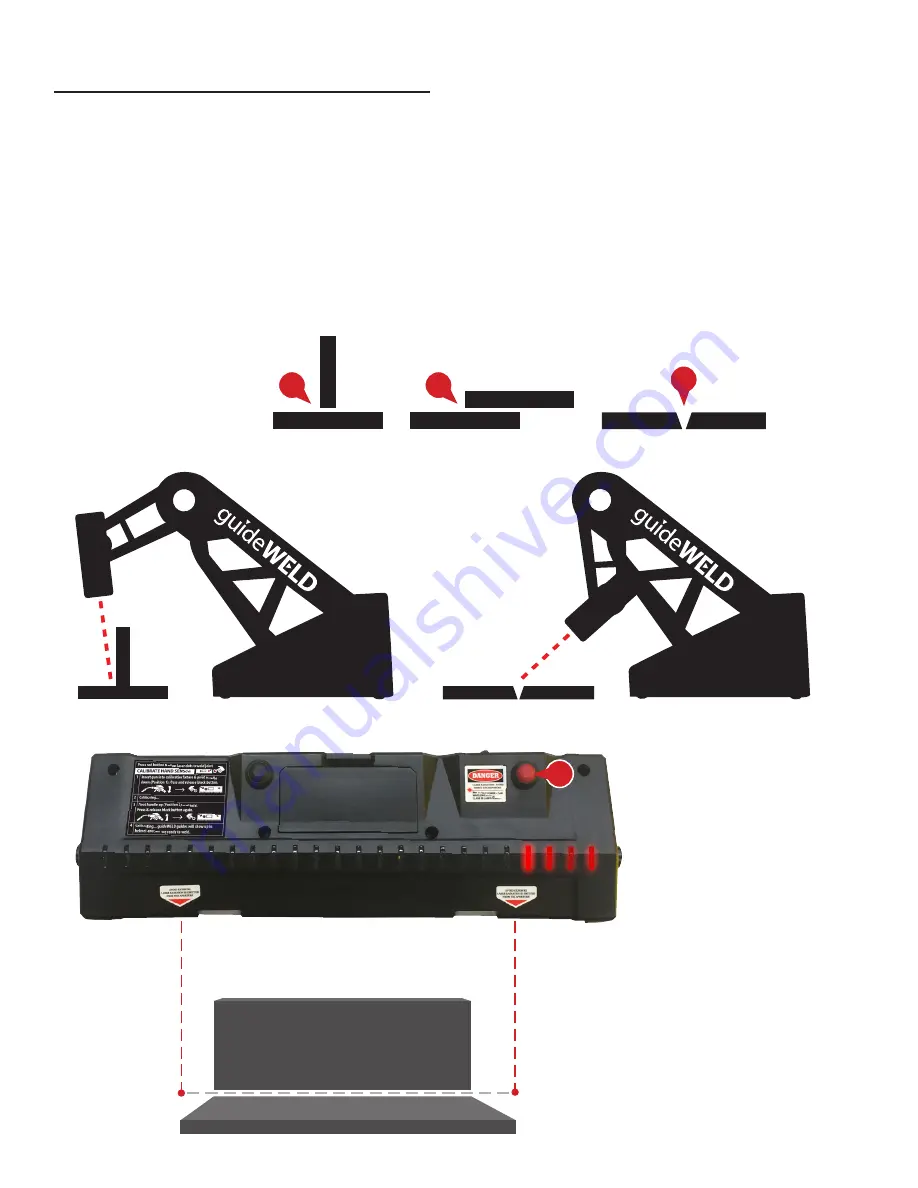

Speed Sensor Alignment

Joint/Coupon types

1. Tee (2F)

2. Lap (2F)

3. V-Groove (1G)

Based on chosen joint type, align Speed Sensor to welding coupon

4. Press the red alignment laser button and align laser dots to weld joint

Tee or

Lap Position

V-Groove or

Lap Position

Joint/Coupon Side Views

Tee Joint/Coupon Alignment*

3

1

2

4

calibration continued on next page >

* Laser dots must be within 1/2 inch of

welding joint line (in front or behind)

for optimal speed feedback.