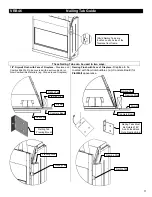

VRB46 -Facing Requirements- ALL UNITS- Chase Not Vented or Vented Chase-

NOTE: ANY MATERIALS COVERING THE FACE OF THE

FIREPLACE BESIDE AND ABOVE THE FIREPLACE

OPENING MUST BE NON-COMBUSTIBLE (i.e. brick,

stone, tile, concrete board). FIREPLACE WITH SCREEN

ONLY (AS SHIPPED) SHOWN HERE.

Notice:

Granite, tile, or other facing materials are not

covered by the fireplace warranty. Natural stone, tile,

and other facing materials may crack or discolor (i.e.

yellowing of lighter colored materials).

NOTE: these issues can be avoided if the Chase is

Vented.

Televisions are not covered by fireplace warranty.

Notice: DurockR Brand Cement Board:

The

manufacturer recommends

CGC SheetrockR Brand

DurabondR 90 Setting- Type Drywall Compound

rather

than a ready-mix product for finishing.

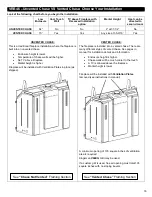

When finishing the wall around the fireplace, it is critical

that the wall covering be fastened properly. It is acceptable

to pre-drill holes and use self-tapping screws which may be

used to fasten a backer for tile, marble, etc. Screws being

installed through non-combustible board should be self-

tapping type with a maximum length of 2 inches.

Do not drill or install longer screws (over 2”) as this

may damage internal components.

We recommend that CONCRETE BOARD (non-

combustible material) be tied in to the entire perimeter of the

fireplace for durability.

Finishing Recommendations

(Obtained from professional

construction contractors and finishers):

Frame unit with metal studs (minimum 20 gauge).

Wooden

studs may be used, but may cause drywall screws to

pop or pull due to wood studs drying out.

Minimum of 1/2” CONCRETE BOARD cement board (this

non-combustible

panel is ULC listed as a wall shield/floor

protector) and fasten to the entire perimeter framing.

Use fiberglass (mesh) tape for all joints in area of the

fireplace.

Use Yellow joint mud (contains high amounts of glue) –

two coats, finishing with one coat of green topping mud,

sand and prep for painting.

If not using a surround, a metal “L” Trim may be used to

finish perimeter of CONCRETE BOARD.

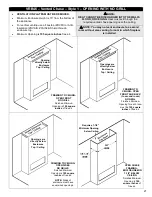

OTHER NOTES:

-

A full single shee

t of non-combustible board (no joints)

above the unit is recommended if possible.

-It is preferred to attach the non-combustible board to

framing only

and not directly to the unit to allow for

expansion and contraction during normal operation.

-Lighter colored painted surfaces may discolor due to heat

exposure.

Non-Combustible Material

Screwed to Framing

REQUIRED:

NON COMBUSTIBLE OVER

UPPER FACE OF APPLIANCE

(46-1/16” x 28-3/4”)

SUGGESTED:

NON COMBUSTIBLE

MATERIAL SCREWED TO FRAMING

(48” x 37-3/4”)

Non-Combustible Material

This area can have a combustible

surface (i.e. drywall, hearth)

This area can have a combustible

surface (i.e. drywall, hearth)

Do not drill or install longer screws (over 2”)

as this may damage internal components

.

12