Instruction Book

30

9828 0934 73

Description

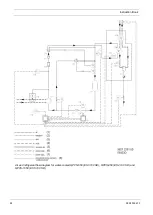

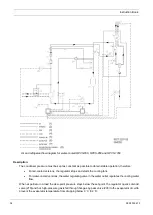

Refrigerant compressor (209) delivers hot, high-pressure refrigerant gas, which flows through condenser

(202), where most of the refrigerant condenses.

The liquid flows through refrigerant dryer/filter (206) to thermostatic expansion valve (204) via sight-glass

(211). The refrigerant leaves the thermostatic expansion valve at evaporating pressure.

The refrigerant enters evaporator (101b), where it withdraws heat from the compressed air by further

evaporation at constant pressure. The heated refrigerant leaves the evaporator and is sucked in by

refrigerant compressor (209) via liquid separator (207).

The dryers are provided with a sight-glass (211). The sight-glass allows the refrigerant flow in the line to be

checked. During normal operation, the liquid flow must be clear. In general, vapor bubbles indicate a shortage

of refrigerant. Note that fluctuations in the load may cause bubbles to pass in the flow for a short time. The

centre of the glass is provided with a moisture indicator which is green when the liquid refrigerant is free of

moisture. It will turn yellow when the refrigerant contains moisture, indicating that the refrigerant dryer/filter

(206) needs to be replaced.

Содержание QED 1050

Страница 2: ......

Страница 4: ...Instruction Book 4 9828 0934 73...

Страница 89: ...Instruction Book 9828 0934 73 89 Dimension drawing of air cooled QED 1050 ES 510 imperial units...

Страница 90: ...Instruction Book 90 9828 0934 73 Dimension drawing of air cooled QED 1050 ES 510 metric units...

Страница 94: ...Instruction Book 94 9828 0934 73 4 2 Installation proposal Example Installation proposal metric unit...

Страница 134: ...02 2021 No 9828 0934 73 Ed 00...