SECTION 5

TROUBLESHOOTING

70

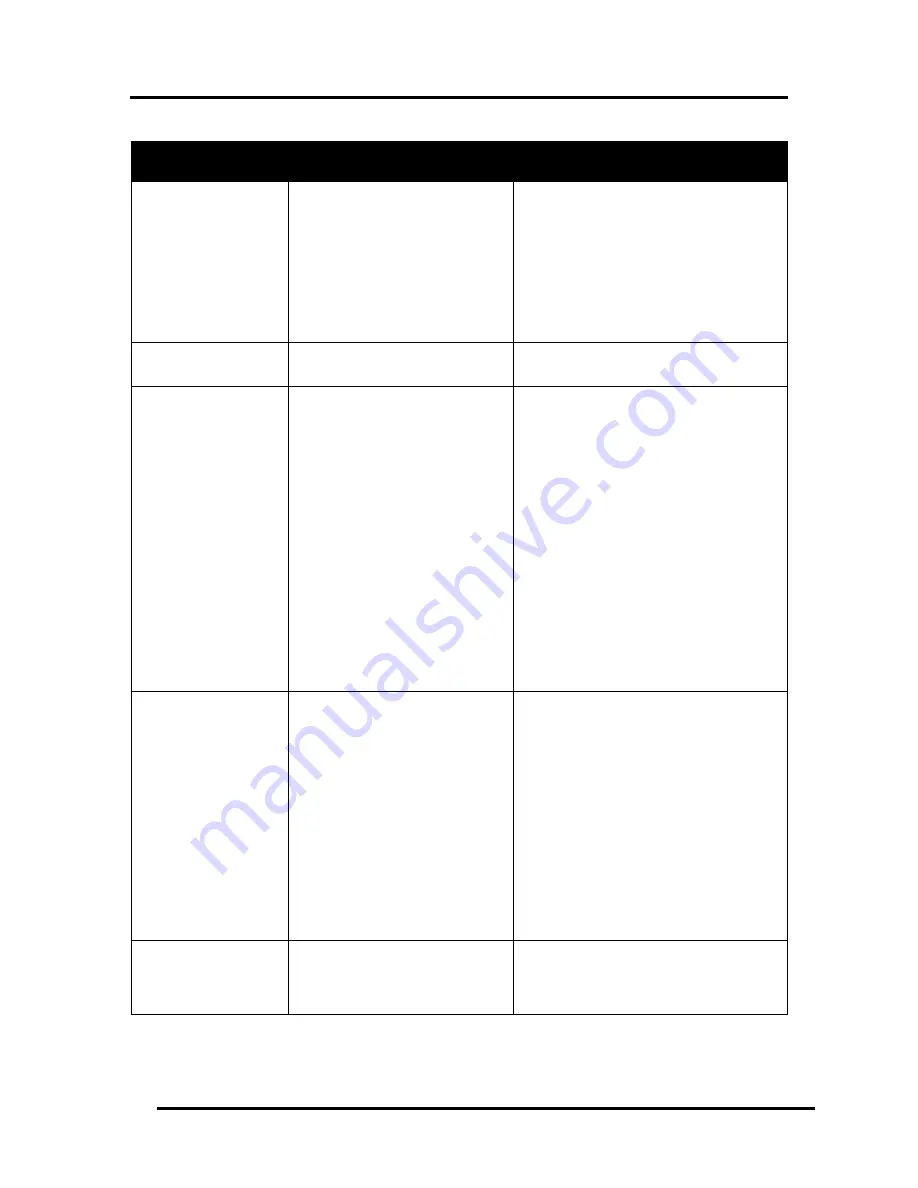

Feeding Problems

CONDITION

PROBLEM

SOLUTION

Intermittent feeding

Media Support Wedge not used.

Side Guides set too tight to media.

Dirty Feed Rollers.

Paper stuck together.

Uneven mail piece.

The Media Support Wedge adds a slope to

the stack and helps feeding.

Readjust Side Guides.

Clean the Feed Roller with distilled water

and a cloth. Do NOT use any solvents as

they may damage Rollers.

Fan media before placing it in Printer.

Tap inserts to front of envelopes and retry.

Multiple feeds

(double feeding)

Separator gap not set properly.

Media stuck together.

Adjust Separators to thickness of media.

Fan the media before loading in Printer.

Failure to feed

Side Guides set too tight to media.

No power to Printer.

Feed gap too tight.

Feed gap too loose.

Material is out of specification.

Motor on, Rollers not turning.

Clutch not engaging (forwarding

rollers turning, but paper feed

rollers not turning)

Motor not driving

No power.

Readjust Side Guides.

Check that power is ON (Main Power

Switch and ON/OFF button) and that the

power cord is plugged in.

Adjust Separator to thickness of media

Adjust Separator to thickness of media.

Maximum thickness is 0.020".

Call Service Support.

Call Service Support.

Call Service Support

See Power Problems in this Section.

Jams

Paper path obstruction.

Paper not loaded properly.

Media Support Wedge not

adjusted properly.

Separators improperly adjusted.

Media curled or bent.

The Separators are worn.

PaperPath Exit sensor is having

trouble seeing the underside of the

media (non-reflective colors).

Feed Encoder dirty / misadjusted.

Clear jam and remove pieces remaining in

print engine.

Load media as instructed in manual.

Adjust Media Support Wedge.

Adjust Separators to thickness of media.

Uncurl media.

Replace Separator tips.

In Toolbox, select (check) “Ignore Exit

Sensor”.

Call Service Support

Right edge of media

being damaged as it

travels through print

engine area

Media is hitting the limits inside

the print engine.

Make sure Adjustable Media Side Guide

is at least 1/8” away from side frame.

If stock is over 9.5” wide; you need to use

narrower stock.

Содержание iJet Press

Страница 1: ...Digital Color Printer OPERATOR S GUIDE ...

Страница 6: ......