- 33 -

4.3. Order of Installation Test Operation

① Check if the connection is right. Turn On the control power.

② Check CT/PT rate on System Config. Menu. If necessary, adjust it following CT/PT rate control.

③ Check connection system on System Config. Menu. If necessary, adjust it.

④ Check & Control Alarm contact’s setting state on DO Config. Menu. If necessary, adjust it.

⑤ On Relay setting menu, check if Relays are correctly setting. If necessary, adjust it.

⑥ After all adjustments, EPIC-R300 works properly.

⑦ If RUN LED on front panel blinks regularly and SYS-FAIL LED is turned off, which

means it works properly.

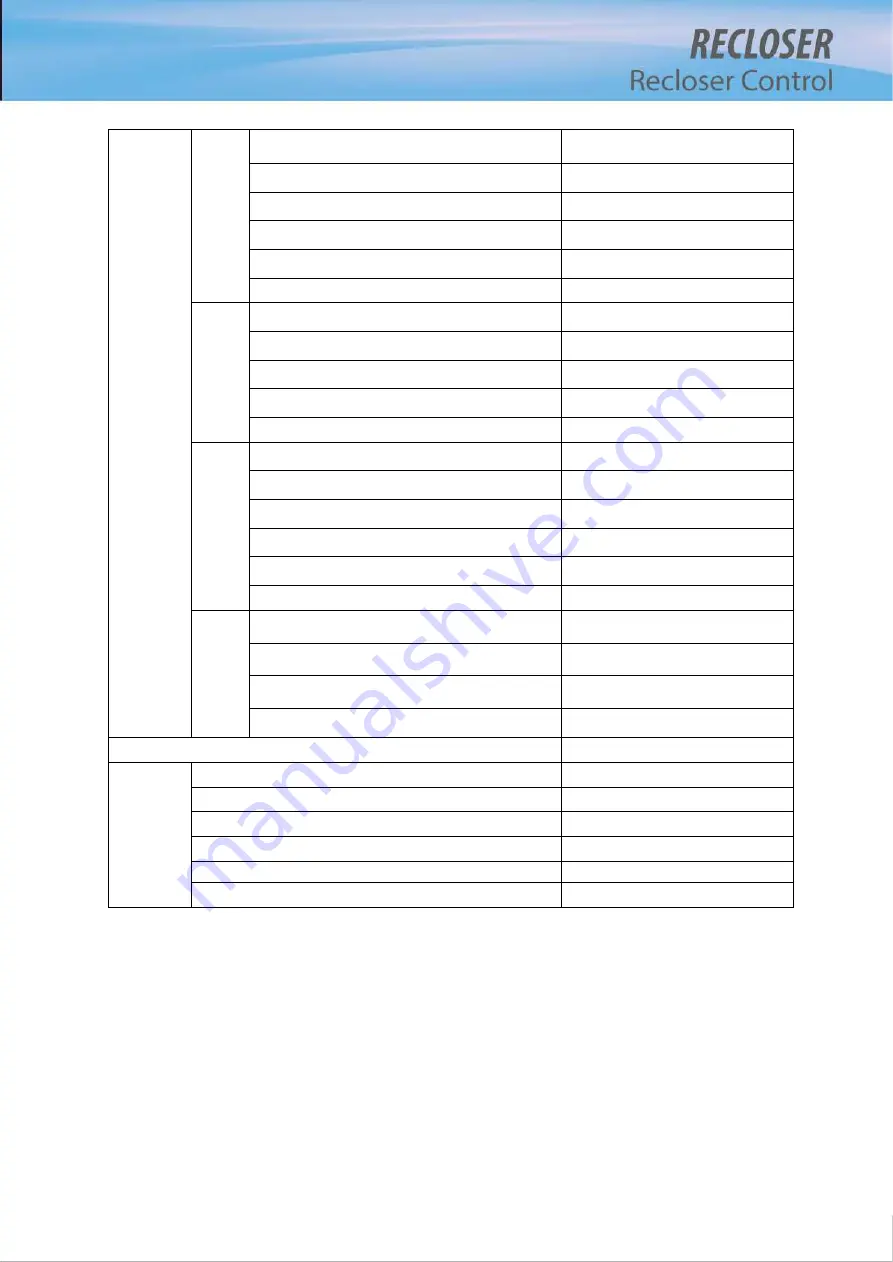

PSTN

Config

PSTN Modem

Select PSTN mode type, PPP, dialup

or SMS

Auto Hangup Time

Set Auto hangup time

Dial Timeout

Set dial timeout

Attempt Delay

Set dial attempt delay time

Max Attempts

Set dial max attempt

Save PSTN Set

Save PSTN related setting

PPP

Config

Our IP Addr

Set our IP address

Their IP Addr

Set their IP address

DNS1 IP Addr

Set DNS1 IP address

DNS2 IP Addr

Set DNS2 IP address

Save PPP Set

Save PPP related setting

SMS

Config

Trip Enable

Set sending trip information

FI Enable

Set sending FI information

Open Enable

Set sending open information

Door Open Enable

Set sending door information

AC fail Enable

Set sending AC fail information

Save SMS Set

Save SMS related setting

Time

sync

option

SNTP sync Enable

Select whether to enable SNTP

SNTP sync Period

Set SNTP cycle duty

Select Time Zone

Select time zone

Save TimeSync Set

Save TimeSync related setting

Time Set

Time setting

Event View

Fault Event

Fault event

Op Event

Display Operation event

Demand I

Display Demand current

Demand P

Display Demand power

Max Demand I

Display Max demand current

Max Demand P

Display Max demand Power

Содержание RECLOSER

Страница 1: ...User Manual Document Version 1 5 Feb 28 2019 http powersys kr http www powersys kr...

Страница 14: ...8 3 5 Mechanical Performance and Size Weight 3 5 kg FRONT VIEW Figure 3 1 Front View...

Страница 15: ...9 SIDE VIEW 343 00 310 00 91 00 Figure 3 2 Side View...

Страница 16: ...10 TOP VIEW 84 0 260 0 225 0 1 0 0t Figure 3 3 Top View...

Страница 17: ...11 REAR VIEW 180 0 120 0 Figure 3 4 Rear View...

Страница 22: ...16 Controller PCB 215 00 103 90 121 10 112 50 112 50 235 00 205 00 Figure 3 8 Controller PCB...

Страница 69: ...63...

Страница 71: ...65 Example configuration file...

Страница 73: ...67 2 TC Curve 1 4 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 1 2 3 4...

Страница 74: ...68 3 TC Curve 5 8 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 5 6 7 8...

Страница 75: ...69 4 TC Curve 8 13 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 8 9 11 13...

Страница 76: ...70 5 TC Curve 14 18 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 14 15 16 18...

Страница 77: ...71 6 TC Curve A D 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting A B C D...

Страница 78: ...72 7 TC Curve E M 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting E K L M...

Страница 79: ...73 8 TC Curve N T 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting N P R T...

Страница 80: ...74 9 TC Curve V Z 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting V W Y Z...

Страница 84: ...78 13 TC Curve ES NI VI 100 101 10 1 100 101 102 ES NI ES VI Current In Multiplies of Setting Time sec...

Страница 85: ...79 14 TC Curve KEPCO N1 N4 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting N1 N2 N3 N4...

Страница 86: ...80 15 TC Curve DEF 1S 10S 100 101 10 1 100 101 DEF 1S DEF 10S Current In Multiplies of Setting Time sec...