10

Connection to the mains supply

Before connecting the plasma cutting plant to the power

supply, check that the data on the plaque corresponds to

the power supply voltage and frequency and that the plant

line switch is in the “O” position.

This plant is designed for a nominal power supply of 230V

50/60 Hz.

Connection to the power supply must be effected using the plug

provided with the plasma cutting plant.

Table 2 lists the rating values for delayed line fuses chosen

on the basis of the nominal maximum power delivered by the

plasma cutting plant and the nominal power supply voltage.

Proceed as follows if you have to replace the plug:

• 2 conducting wires are needed for connecting the machine

to the supply

• The third, which is YELLOW GREEN in colour is used for

making the “EARTH” connection.

NOTE: If extensions of the power supply cable are used, they

must be of adequate cross section and never inferior to that of

the cable supplied.

Instructions for use

COMMAND AND CONTROL UNITS (Fig. A)

Pos. 1

Potentiometer for regulation of cutting current.

Pos. 2

White LED - power supply on. When on the system

is powered and ready for use.

Pos. 3

Red LED - plasma cutting cycle control.

Pos. 4

Yellow LED: signals intervention of overheat cutoff

Pos. 5

Earth wiring.

Pos. 6

Plasma torch.

Pos. 7

Main switch.

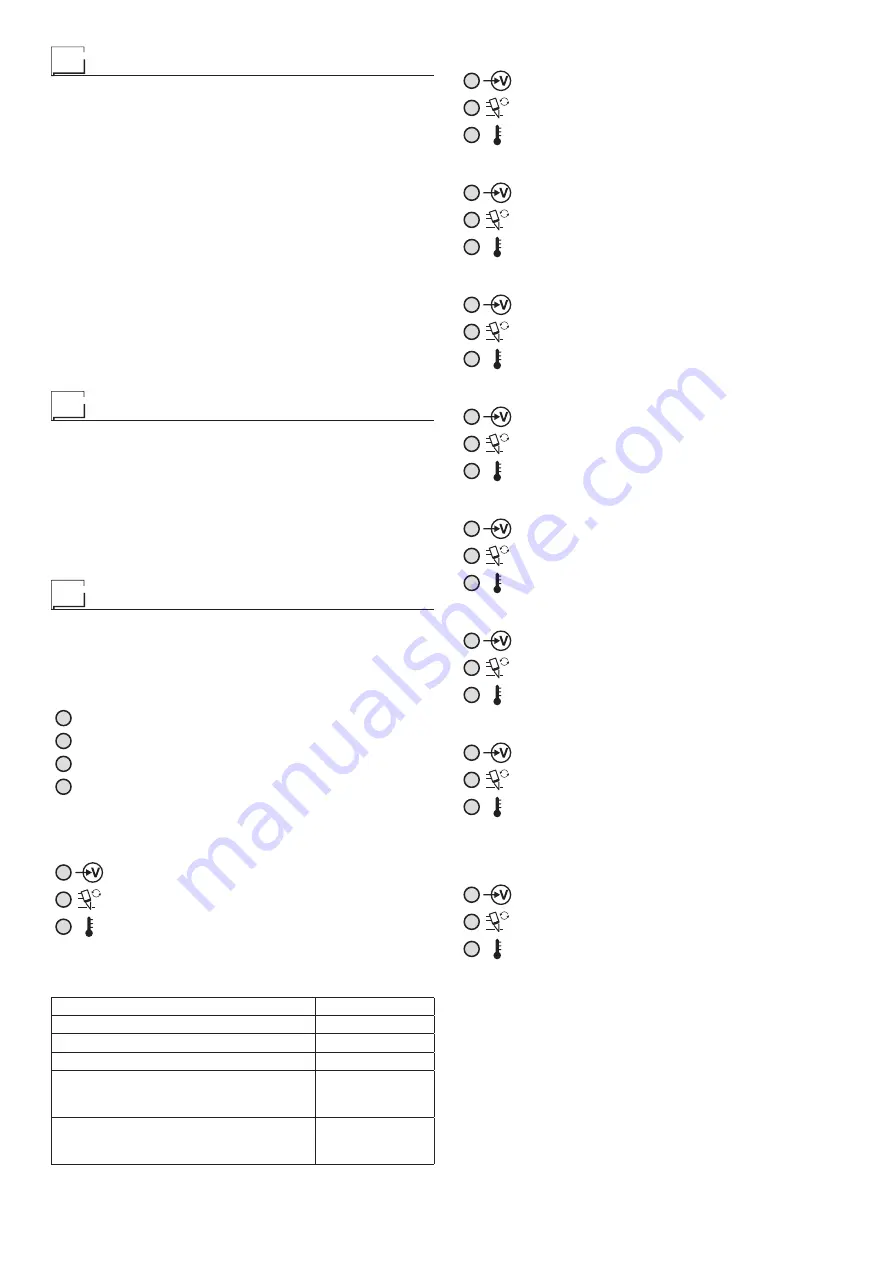

LED Sequences

The following are the principal combinations or sequences

which the LEDs on the

SHARK 25

rack panel may assume.

Important! Read this paragraph to fully understand correct plant

operation.

LED symbols legend

ON

LED on

OFF

LED off

LOW INT

LED flashing slowly

FAST INT

LED flashing rapidly

POWER ON

This sequence lasts a few seconds only from the moment in

which the operator actions the plant power switch.

ON

The plant has just been switched on

and the microprocessor is verifying the

correct function of each component.

FAST INT

FAST INT

PAUSE

ON

The plant is functional but no cutting

operations are being executed at this

time.

OFF

OFF

EFFECTIVE WORKING

ON

The plant is functional and the operator is

cutting at this time.

ON

OFF

“TIME OUT” PILOT NOT TRANSFERRED

ON

Alarm! The pilot arc has not transferred

to the item to be cut. The LED flashes for

some 15 seconds.

FAST INT

OFF

THERMOSTAT CUT OUT

ON

Alarm! Protective thermostat triggered.

Wait for the yellow LED to go off, several

minutes, the recommence cutting.

OFF

ON

UNDER-VOLTAGE OR OVER-VOLTAGE

ON

Alarm! Incorrect power supply voltage.

Power off the plant and verify that line

power corresponds to the data on the

plaque.

LOW INT

OFF

AIR PRESSURE

ON

Alarm! Air pressure insufficient (<2.5 bar).

Power off the plant and verify that the air

compressor is functioning correctly.

LOW INT

OFF

“SAFETY” TORCH ACTIVE

ON

Alarm! External torch nozzle mounted

incorrectly. Power off the plant and verify

- remount the plasma torch correctly.

LOW INT

OFF

POWERING OFF

This sequence lasts a few seconds from the moment in which

the operator actions the machine power supply switch.

ON

The plant has just been powered off

and the microprocessor is verifying the

correct function of each component.

FAST INT

OFF

Table 2

Model

SHARK 25

Power input @ I

2

Max

kVA

5

Delayed fuse

A

16

Duty cycle @ 35% (40°C)

A

25

Mains supply connection cable

Length

Section

m

mm

2

2,3

3×1,5

Earth cable

Length

Section

m

mm

2

3,5

4

Содержание SHARK 25

Страница 72: ...72 D A 95 B C E A B 6 25 7 7 A LED 2 A LED 3 A LED SHARK 25 SHARK 25 F 3 LED rack SHARK 25 LED LED E F D...

Страница 73: ...73 7 A LED 2 A inverter LED 4 A inverter inverter LED LED 3 A 2 5bar inverter Undervoltage overvoltage...

Страница 77: ...77 B SHARK 25 3 1 1 7 A 2 3 2 A 3 1 A 4 A C B C 5 2 A 3 A 1 2 3 4 5 6 7 A B C A...

Страница 78: ...78 D A 95 B C E A B 6 25 7 7 A 2 A 3 A SHARK 25 SHARK 25 F 3 SHARK 25 E F D...

Страница 79: ...79 7 A 2 A 4 A 3 A 2 5...