for the MIG welding torch (Fig 4) This accessory

has a long life-time if periodical controls of the

gas nozzle and the wire feeder tip are carried out

(Fig 4A) (Fig 4B).These parts must be kept well-

cleaned and intact. Replace the wire liner when

the wire no longer threads correctly.

5.3 CONNECTOR FOR MIG WELDING with a

Spool or Push-Pull torch

1) Connect the earth cable to the appropriate ‘-‘

socket. (12 of figure 1). Insert by lining up the key

with the groove and turn in a clockwise direction

until it stops. Do not fasten too tightly!

2) Connect the torch to the appropriate socket

on the front of the device (16 of Fig 1),turning in

a clockwise direction until it stops. Do not fasten

too tightly!

3) Insert the connector of the torch into the

appropriate female socket.

MIG WELDING: Connect the pressure regulator

to the cylinder, after which attach the gas tube

of the torch to the latter. MIG welding is usually

carried out with a constant current, with a positive

pole (“+ “see fig.5).

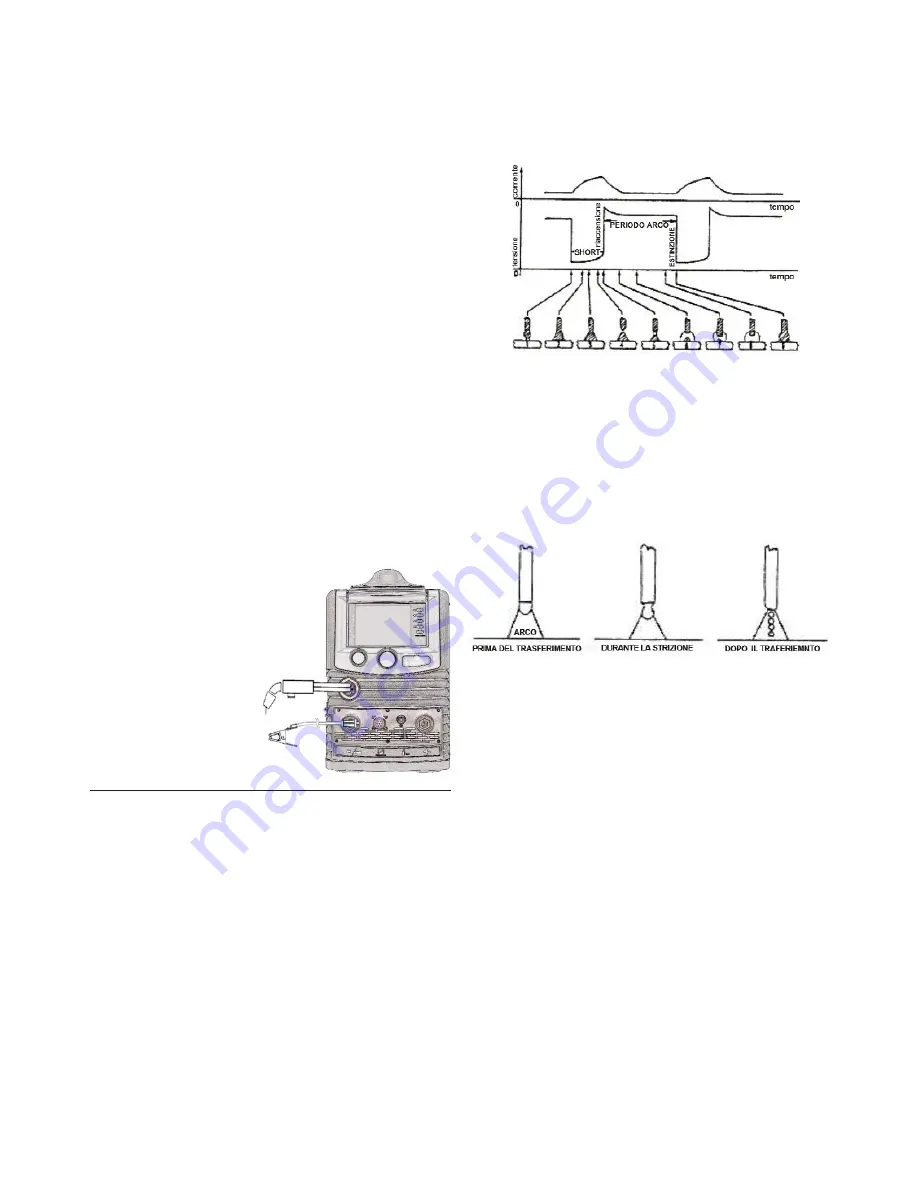

SHORT ARC (short-circuit transfer):this brings

the electrode into direct contact with the

weld pool, which creates a short-circuit that

extinguishes the arc, after which the arc reignites

and the cycle is repeated.

. - the tension directly influences the appearance

of the welding seam, but the dimensions of

the welding surface can be varied, according

to requirements, by manual movement of the

torch to obtain variable deposits with a constant

tension.

- the speed of the movement of the wire is in

relation to the welding current.

7. ADJUSTING THE WELDER

Once the welding tension has been set, maintain

the length of the electric arc between 5 and 10

mm and adjust the wire speed to achieve the best

welding results. Initially, carry out a welding test

on a well-cleaned sample, free of any coating,

rust or paint.

NOTE The torch trigger controls the following

functions:

- gas flow

- wire movement

- welding current

Fig.5

SPRAY ARC (spray transfer):

this allows the droplets to detach from the

tip of the electrode, which successively reach

the weld pool.

The fact the arc is visible, reduces the need

for the operator to strictly observe the adjustment

tables, allowing for direct control of

the welding pool.

The MIG torch cable

is connected to the

Euroconnector(16

offig.1),

whilst

the earth cable of

the work piece is

connected to the

‘-‘socket on the

front(12 di fig.1).

At this stage adjust the welding current using

the potentiometer (9 of Fig.1), situated on the

front panel. The diameter of the electrode and

the welding current settings must be selected

according to the thickness of the workpiece.

6. STRIKING AN ARC IN MIG WELDING The

MIG-MAG welding process is when an electric arc

is created between a consumable wire and the

workpiece, protected within a gas atmosphere.

This atmosphere can be either inert (Argon) or

active (CO2 or a mixture of Argon and CO2).The

wire is continuously fed through a torch by a wire

feeder to the weld pool. A solid wire or flux-cored

wire can be used. The transfer methods of the

filler material define different arc types:

Содержание DP231C

Страница 1: ...ISSUE 2 User Manual DP231C...

Страница 2: ......

Страница 3: ......

Страница 4: ......