29

“

Horn

”

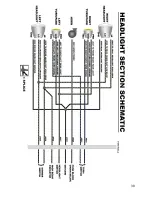

The

Headlight Section

has a single wire

dedicated for connection to a horn.

*

Most horns

ground through their mounting and only require a

power connection. This wire is:

Black/Green

: 16 gauge wire, printed

[HEADLIGHT

SECTION] #924 HORN POWER

, this is a power wire

that comes from the fuse block mounted horn relay

which is ground activated by the horn button on the

steering column. This wire will only have power when

the horn button is pressed.

Route the

#924

wire to the horn. If you have to pass this wire through any

metal surfaces, you will find small grommets in the parts kit to protect the

wire.

If you have a tab on the horn, locate the

terminal and connector, seen to the right,

provided in the parts kit.

Ring terminals and heat shrink have been

provided for those with “screw” or “post &

nut” connections.

If your horn has a wire to connect to, then

a splice and heat shrink will be needed.

*

If your horn requires a ground wire, use a piece of scrap wire that was cut from

the any of the black

#969

ground wires on the driver side headlight or turn/park light

connections to connect the ground on the horn. Using a ring terminal from the parts kit,

attach the other end of the ground wire to a chassis ground source on the vehicle.

“Right Turn/Park Light” & “Right Headlamp”

The connections mentioned above all connect in the same manner as those on

the left/driver side. The only difference you will find is the Turn signal wire for the right

turn signal has a different color stripe that one used for the left turn signal. The right

Turn signal will be:

Black/ Blue

: 18 gauge wire, printed

[HEADLIGHT SECTION] #925 TO RIGHT FRONT

TURN SIGNAL

, this wire is the turn signal power. This wire goes into a splice with the

Black/ Blue wires going to the right turn indicator light and to the wire coming from the

turn signal switch. This wire will have interrupted switched power from the turn signal

flasher any time the left turn signal is activated and the ignition is in the ON position and

interrupted battery power from the hazard flasher any time the hazard switch is in the

ON position.

This concludes all of the connections in the

Headlight Section

of the engine

harness. Go back and inspect the harness layout and once satisfied it is free of moving

parts and sharp edges tighten any loose zip ties.