NANO 1000S Polisher

I

NSTRUCTION

M

ANUAL

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: [email protected] W eb: https://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

49

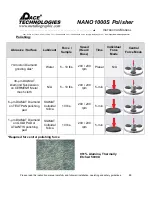

4.8.3.11 CLASS 11: Glass and Minerals (Example: Alumino-silicate Glass Ceramic)

Polishing:

Glass ceramics are unique materials that

have very small crystalline structures.

The primary advantage of glass ceramics

is that they produce very interesting

thermochemical properties because

they are impervious to thermal shock.

Proper microstructural preparation of

these materials require minimizing

damage during cutting or sectioning.

Therefore, the most important step in

the preparation of glass ceramics is

sectioning. If the glass ceramic is chipped or excessively cracked during sectioning,

it may be impossible to remove this damage. Wafer sectioning with a fine grit

diamond wafering blade is essential.

Planar grinding is accomplished with diamond on a metal mesh cloth to minimize

cracking and subsurface damage. For rough polishing, the use of a low-napped

polishing pad with polycrystalline diamond and colloidal silica eliminates most of the

surface and subsurface damage. Final polishing is accomplished with a resilient

porous urethane polishing pad such as BLACKCHEM 2 using SIAMAT colloidal

silica.

Sectioning:

Diamond Wafering Blade - Medium Grit / Low Concentration

Mounting:

Castable Mounting with Epoxy or Acrylic resins.