NANO 1000S Polisher

I

NSTRUCTION

M

ANUAL

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: [email protected] W eb: https://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

23

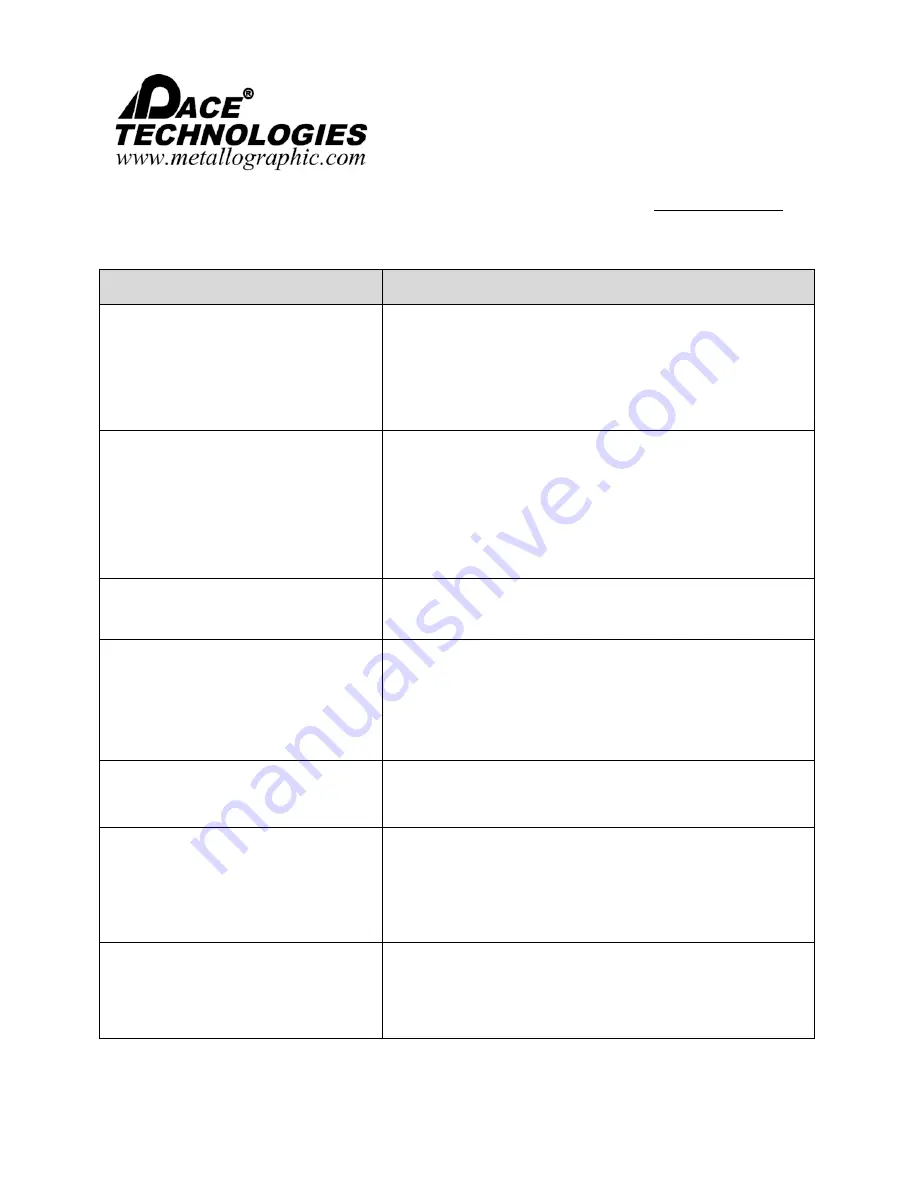

Rough Polishing Guidelines

Materials

Recommendation

Metals

(Ferrous, Non-ferrous, Tool

Steels, Superalloys, etc.)

Rough polishing usually requires two

polishing steps

(Ex: a 6-micron diamond followed by a 1-

micron diamond on low-napped polishing

cloths).

Ceramics and Ceramic

Matrix Composites (CMC)

Low-napped polishing pads using

polycrystalline diamond, alternating with

colloidal silica.

This provides a chemical mechanical

polishing (CMP) effect which results in a

damage-free surface.

Polymer Matrix

Composites (PMC)

Diamond-lapping films are

recommended.

Biomaterials

Low-napped polishing pads with

polycrystalline diamond, alternating with

colloidal silica.

Alternatively, diamond-lapping films may

work well.

Microelectronic Specimens

Diamond-lapping films are

recommended.

Plastics and Polymers

800 and 1200 grit SiC abrasive paper is

recommended.

Plasma Spray Materials

Diamond-lapping films or low-napped

polishing pads with alternating diamond

and colloidal silica abrasives.