NANO 1000S Polisher

I

NSTRUCTION

M

ANUAL

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: [email protected] W eb: https://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

39

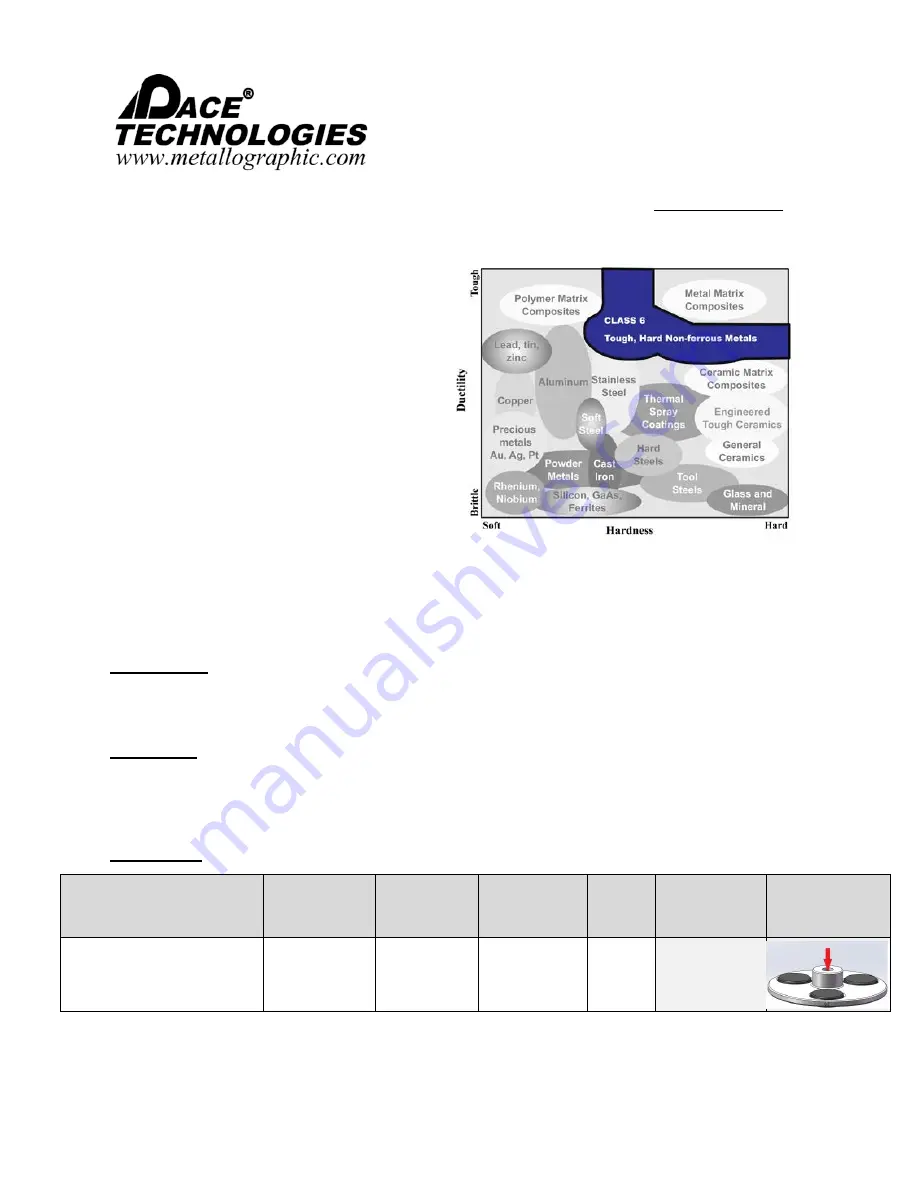

4.8.3.6 CLASS 6: Tough, Hard Non-Ferrous Metals

(Example: Iron-Cobalt-Nickel Alloys)

Abrasive / Surface

Lubricant

Force /

Sample

Speed

(Head /

Base)

Time

Individual

Force

Mode

Central

Force Mode

120 grit SiC paper*

240 grit SiC paper*

Water

5

– 10 lbs.

200 / 200

rpm

Planar

1-min

N/A

Superalloys are high-performance

alloys which exhibits excellent

mechanical strength and creep

resistance at high temperatures, good

surface stability, and corrosion and

oxidation resistance. The base

element in Superalloys are nickel,

cobalt, nickel-iron.

Iron-cobalt-nickel alloys are relatively

easy to polish by standard

metallographic techniques. However,

the results can be significantly

improved by using finely graded

nanometer alpha alumina polishing

solutions.

Sectioning:

MAXCUT Abrasive blade (Cat. No. MAX-C or MAX-I series)

Mounting:

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression

mounting resins.

Polishing: