SECTION 4 - BOOM & PLATFORM

4-8

– JLG Lift –

3121623

pads from the top, sides and bottom of the base

boom section.

10.

Using an overhead crane or suitable lifting

device, remove mid and fly boom sections from

base section. Note: When removing mid and fly

boom sections from base boom section, retract

wire rope must be dragged along with boom

sections.

11.

Remove hardware which secures the wear pads

to the rear end of mid boom section; remove the

wear pads from the top, sides and bottom of the

mid boom section.

12.

Remove hardware which secures the sheave

guards and sheave assemblies to mid boom sec-

tion, remove sheave assemblies from mid boom

section.

13.

Remove hardware which secures the wear pads

to the front of mid boom section; remove wear

pads from the top, sides and bottom of the mid

boom section.

14.

Using an overhead crane or suitable lifting

device, remove fly boom section from mid sec-

tion. Note: When removing fly boom section

from mid boom section, retract wire rope must

be dragged along with fly boom section.

15.

Remove hardware which secures the wear pads

to the rear end of fly boom section; remove wear

pads from the top, sides and bottom of the fly

boom section.

16.

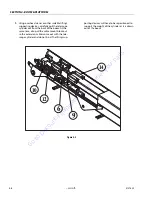

When removing wire rope from fly boom sec-

tion, push the cable into fly boom. Route wire

rope back through holes in the side of the fly

boom section.

Figure 4-11.

4.3

INSPECTION

Checking Wear And Deformation Of Ropes And

Pulleys

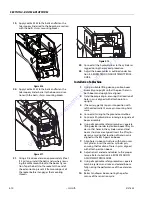

If only one of the following situations is detected the

ropes or pulleys must be replaced.

1.

Check that there are no broken threads on the

surface of the rope, in the internal area or in cor-

respondence with the cable socket.

Figure 4-12.

2.

Check that there are no signs of corrosion on the

rope.

3.

Check that there are no signs of kinking, crush-

ing or deformations of any type on the rope.

Figure 4-13.

4.

Check the condition of the fixing pins of the out-

let pulley and extensions return.

5.

Check the wear of the pulley grooving using a

profile comparator. As indicated in the figure it is

necessary to check that the outline of the com-

parator corresponds with the base of the groov-

ing.

Figure 4-14.

6.

Check that there are no signs of ovalisation, wear

or any other type of deformation on the pulleys.

Go

to

Discount-Equipment.com

to

order

your

parts