SECTION 3 - CHASSIS & TURNTABLE

3-2

– JLG Lift –

3121623

Checking The Rubber Tracks

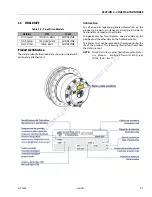

Figure 3-3. Rubber Track Structure

The structure of the rubber track is illustrated in Figure 3-3.

The steel ropes and the metal core are imbedded into the

rubber. The carved profiles are used to give traction when

moving over loose land. They are situated in the lower

part resting on the ground, while the wheel guides situ-

ated inside the track, prevent the track from escaping

from the guide rollers.

CAUSES OF DAMAGE

1.

Breakage of the steel ropes

Excessive tension causes the steel ropes to break

in the following conditions:

a.

when stones or foreign bodies accumulate

between the track and the under-carriage

frame;

b.

when the track escapes from its guide;

c.

in the case of strong friction such as rapid

direction changes.

2.

Wear and breakage of the metal cores

As for breakage of the steel ropes, stated above,

excessive tension may cause the metal cores to

bend or break, as may the following causes:

a.

incorrect contact between toothed wheel

and track;

b.

breakage of internal rollers;

c.

functioning on sandy land.

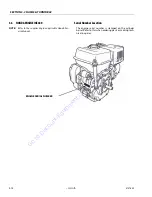

Figure 3-4.

3.

Separation of the metal cores

a.

The metal core acts as a type of adhesive of

the rubber between the core itself and the

steel ropes. Separation may be caused by

excessive tension as breakage of the ropes

for the following reasons:

b.

The metal cores have been wound by the

worn toothed wheel as indicated in the fig-

u r e . W h e n t h i s w e a r a n d a b r a s i o n i s

detec ted, the toothed wheel must be

replaced as soon as possible.

c.

If it breaks, as stated in item 2, "Wear and

breakage of the metal cores", the track must

be replaced because this damage leads to a

complete loss of functions.

4.

Abrasion and fatigue cracks

a.

The cracks at the base of the carved profile

occur due to bending fatigue of the rubber

caused by the toothed wheel and the track-

tensioning wheel.

b.

The cracks and bends on the edge of the

rubber are due to manoeuvres with the

track in presence of cement kerbs and

edges.

Figure 3-5.

c.

The cracks and abrasions in the rubber on

the tracks of the roller guide originate from

fatigue from the compression of the rubber

by the weight of the wheel, together with

functioning on sandy land, or repeated and

abrupt changes of direction.

d.

Abrasion of the carved profiles may occur

especially if slewing on concrete surfaces or

on gravel or hard surfaces are carried out.

PATTERN

WHEEL SIDE

SPROCKET

HOLE

METAL CORE

STEEL WIRE

g

WORN PARTS

CRACK

Go to

Discount-Equipment.com

to

order your

parts