SECTION 3 - CHASSIS & TURNTABLE

3121623

– JLG Lift –

3-33

These Instructions are valid for machines with no engine

key switch.

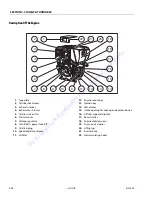

Figure 3-63.

Remove the engine hood to access to the harness and

engine left side, to identify the wires with plug connectors.

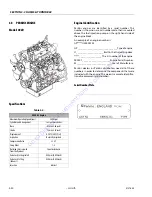

Figure 3-64.

Disconnect the plug circled.

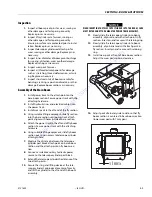

Figure 3-65.

On Female connector jump the follows wires:

•

Pin12 (12 Volt supply) battery positive terminal.

•

Pin 7 (Glow plugs) hook up if necessary for few second

only.

•

Pin 5

•

(Starter) for a moment utilize hook up this pin as key

starter.

Go

to

Discount-Equipment.com

to

order

your

parts