SECTION 5 - HYDRAULICS

5-12

– JLG Lift –

3121623

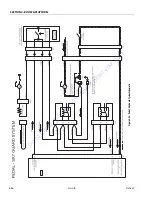

Boom component manifold valves are fed by pressure line "A" through deviator valve and oil rate is controlled through the

proportional valve managed by the control module.

Depending on the movement required, proportional valve will open accordingly regulating the proper oil rate, than the

relevant ON-OFF valves (one each movement) will open addressing the oil to the relevant cylinder or actuator.

When the proportional valve coil is not fed, oil is sent to the drainage and then to the tank.

The maximum pressure valve has to be calibrated as indicated on use and maintenance manual at 200 bar with Diesel

engine or 180 bar with electric motor (185 bar for lithium machine).

Through boom component manifold valves feed the turret rotation motor, the cylinder for moving 1st and 2nd booms, the

cylinder for moving the 3rd boom, the telescope cylinder, the jib cylinder, the basket rotation actuator and the basket lev-

elling circuit.

On each cylinder an actuator is installed a couple of calibrated valves, one each direction, when movement is in progress

on one direction the opposite valve is piloted to open letting oil flow back to the manifold valve block.

When these valves are not piloted oil flow is avoided so that they keep the cylinder and actuator position against external

forces or in case of an hose damage.

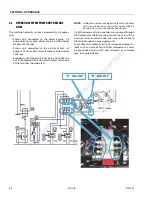

First And Second Booms

1st and 2nd booms are moved together by one cylinder through the connection rod designed to obtain a double parallel-

ogram system, this cylinder is equipped with an internal sensor that measures its opening position.

COUPLE OF

CALIBRATED

VALVES

CONNECTING ROD

Go

to

Discount-Equipment.com

to

order

your

parts