SECTION 3 - CHASSIS & TURNTABLE

3-10

– JLG Lift –

3121623

Bolting The Slew Drive

DO NOT USE IMPACT SCREWDRIVERS. USING AN IMPACT SCREW-

DRIVER MAY CAUSE IMPERMISSIBLE DEVIATIONS BETWEEN THE BOLT

TIGHTENING FORCES. FAILURE OF THE BOLTED UNION WITH THE

MOUNTING STRUCTURE MAY CAUSE SEVERE PERSONAL INJURY OR

MATERIAL DAMAGE.

NOTICE

MOUNT THE SLEW DRIVE IN UNSTRESSED STATE.

Strictly comply with the procedure specified below to

avoid impermissible deviations between the bolt tighten-

ing forces:

NOTICE

FIRST FASTEN THE HOUSING, THEN FASTEN THE TOOTHED BEARING

RING!

1.

Use medium strength Loctite (Loctite 243) on

screws.

2.

Pretension the bolts, with washers if required,

crosswise in 3 steps, 30%, 80%, and 100% of the

tightening torque, or the hydraulically applied

pretension force.

3.

In this process turn the unscrewed ring several

times. Repeat the procedure for the bearing ring

that has not yet been bolted.

If using a hydraulic bolt-tensioning cylinder the tension-

ing forces for the bolt pretension should not exceed 90%

of yield strength.

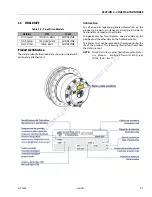

Figure 3-23. Tighten crosswise

1)

F

M

for hydraulic bolt-tensioning cylinder pretension to

85% of yield strength.

1)

F

M

for hydraulic bolt-tensioning cylinder pretension to

85% of yield strength.

Table 3-3.

MOUNTING BOLT

DIMENSIONS

MOUNTING PRETENSION FORCE

F

M

1)

STRENGTH CLASS 10.9 in

kN

lbs

M24

282

63396

M27

367

82505

M30

448

100714

M33

554

124544

M36

653

146800

M42

896

201429

M45

1043

234476

M48

1177

264600

M52

1405

315857

M56

1622

364640

M60

1887

424215

M64

2138

480642

M68

2441

548759

Table 3-4.

MOUNTING BOLT

DIMENSIONS

MOUNTING PRETENSION FORCE

F

M

1)

STRENGTH CLASS 10.9 in

kN

lbs

1 – 8 UNC

301

67668

1 1/8 – 7 UNC

379

85203

1 1/4 – 7 UNC

481

108133

1 3/8 – 6 UNC

573

128816

1 1/2 – 6 UNC

697

156692

1 5/8 – 6 UNC

832

187041

1 3/4 – 5 UNC

942

211770

Go to

Discount-Equipment.com

to

order your

parts