SECTION 4 - BOOM & PLATFORM

3121623

– JLG Lift –

4-9

Assembly

NOTE:

When installing fly section wear pads, install same

number and thickness of shims as were removed

during disassembly.

1.

Measure inside dimensions of the base and mid

sections to determine the number of shims

required for proper lift.

2.

Measure inside dimensions of the mid section to

determine the number of shims required for

proper lift.

3.

Install side, top and bottom wear pads to the

rear end of fly section; shim evenly to the mea-

surements of the inside of mid section.

4.

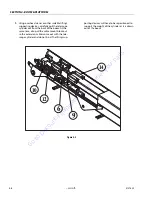

Install retract wire ropes into rear end of fly sec-

tion, route wire ropes thru holes in side of fly

boom section and pull into slot.

Figure 4-15.

5.

Install side, top and bottom wear pads to the

rear end of mid section.

NOTICE

WHEN ASSEMBLING BOOM SECTIONS, ENSURE THAT THE BOOM SLID-

ING TRAJECTORIES HAVE BEEN CLEARED OF CHAINS, TOOLS, AND

OTHER OBSTRUCTIONS.

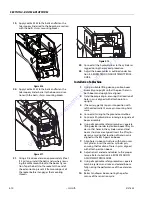

6.

Slid fly boom section into the mid boom section.

Adjust boom, if necessary, for a total of 1/16 inch

(0.062) clearance.

7.

Install wear pads into the forward position of the

mid boom section. Adjust boom, if necessary, for

a total of 2/10 inch (5.08mm) clearance.

8.

Properly position the retraction wire rope

sheaves assemblies at the rear end of the mid

boom section; ensure all sheave-to-mounting

block attachment holes align. Install the sheave

pins and secure them with mounting hardware.

Position retract wire ropes onto the sheaves.

9.

Install sheave guards to rear end of mid boom

section and secure with mounting hardware.

10.

Slide mid boom section into the base boom sec-

tion. Allow the retraction wire ropes to trail

between the bottom surfaces of boom sections.

Adjust boom, if necessary, for a total of 1/16 inch

(0.062) clearance.

11.

Install wear pads into the forward position of the

base boom section. Adjust boom, if necessary,

for a total of 2/10 inch (0.20) clearance.

12.

Install sheave block to bottom of base boom sec-

tion and adjust block so that retract wire ropes

do not come into contact with boom surfaces.

13.

Install wire rope threaded ends thru attachment

holes in the bottom of base boom section.

Loosely install nuts and jam nuts onto the

threaded ends of wire ropes.

14.

Pull the boom sections out to approximately

where they were extended to for telescope cylin-

der removal.

15.

Install a new extend sheave on the end of the

telescope cylinder.

16.

Route new extend cables around the telescope

cylinder. Loosely fasten the threaded end of the

cables to the rod end of the telescope cylinder

with the adjusting nuts and lock nuts. Install the

opposite end of the cables in the cable mount

block.

17.

Use tape or tie straps to fasten the cables to the

telescope cylinder assembly. It is important that

the tape or straps be strong enough to hold the

cable in place yet weak enough to break and fall

away when the cables are adjusted.

NOTICE

WHEN PUSHING THE TELESCOPE CYLINDER INTO THE BOOM, IT MAY

BE NECESSARY AT SOME POINT TO TURN THE CYLINDER SLIGHTLY IN

ORDER TO CLEAR ASSEMBLIES MOUNTED WITHIN THE BOOM. CARE

MUST BE TAKEN TO MOVE THE CYLINDER SLOWLY INTO THE BOOM.

DAMAGE TO COMPONENTS MAY RESULT FROM FORCIBLE IMPACT

WITH THESE ASSEMBLIES.

NOTE:

The telescope cylinder weighs approximately 600

lbs. (275 kg).

18.

Using adequate lifting equipment, carefully

push the telescope cylinder assembly and cables

back into the boom.

Go to

Discount-Equipment.com

to

order your

parts