Oki Data CONFIDENTIAL

44158801TH Rev.2

307 /

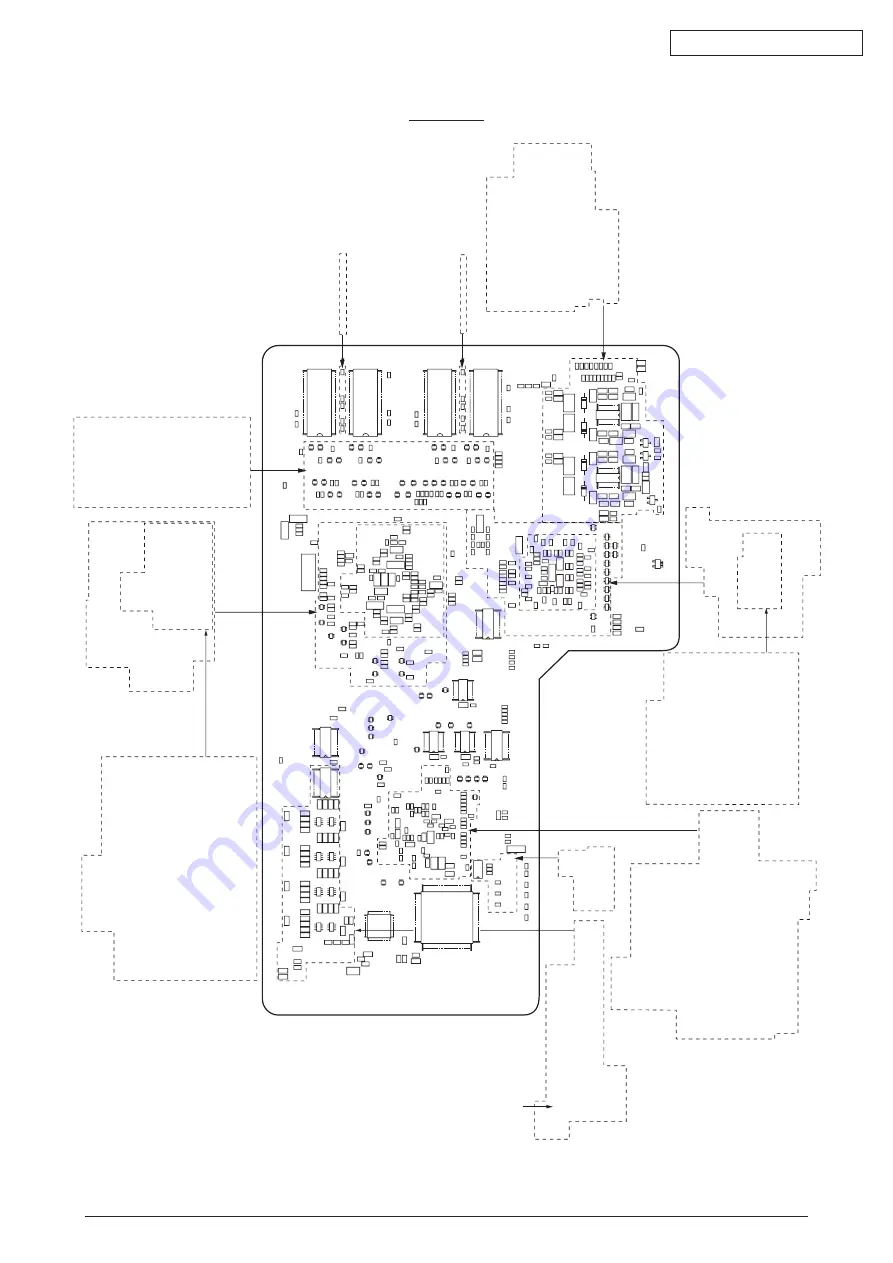

Solder side

C536 C530 C527

C525

C774

C765

C708

C713

C667

C697

C687

C764

C763

C762

C773

C743

C735

C734

C725

C717

C712

C711

C704

C694

RM573

C718

C753

C752

C744

C736

C701

C690

C686

C684

R661

R771

RR504

RRM504

RRM508

RR508

RR507

RR506

RR505

R769

IC506

DBF516

RRM507

RRM503

RRM506

R711

R709

R745

R744

R710

RM570

RM566

RM560

RM571

RM567

RM552

RM576

RM574

RM684

RM580

RM561

RM553

RM550

RM547

RM545

RM542

RM540

RM528

RM524

RM537

RM534

RM539

RM536

RM521

RM525

RM530

RM519

RM516

R666 R663

R660

R667 R659

R658

R655 R650

R645

R612

R608

R631

R649

R630

R597

R611

R629

R600

R598

RM546

RM532

RM531

RM520

RM517

R707

R706

R743

R726

R702

R703

R700

R727

R725

RM577

RM575

RM583

RM579

C779

C757

C802

C816

C813

C812

C811

C809

C797

C789

C790

C748

C747

C728

C729

C730

C731

C714

C715

C716

C732

C733

C709

C710

C721

C722

C741

C756

C769

C742

C784

C785

C770

C771R683

C723

C724

C698

C651

C689

C688

C699

C749

C750

C727

C798

C794

C783

C778

C780

R677

C791

C800

C801

C795

C796

C793

C792

C782

C781

C767

C768

C761

C737

C738

C739

C740

C755

C754

C746

C745

C766

C808

C815

C823

R718

R717

R715

R713

R712

R708

RM578

RM582

RM581

R742

R741

R740

R739

C831

C830

R729

R722

R721

R720

R719

C814

C702

R736

R734

R692

R675

R671

R691

R689

C786

R732

R731

C827

C822

C829

RM573

RM572

RM549

RM548

RM555

RM556

RRM502

RRM505

RRM501

DBF515

DBF514

DBF513

DBF512

DBF511

DBF510

DBF509

DBF508

DBF507

DBF506

DBF505

DBF504

DBF503

DBF502

DBF501

C858

C703

R656

R693

R652

R647

R643

R642

R697

DBF532

DBF531

DBF530

DBF529

DBF528

DBF527

DBF526

DBF525

DBF524

DBF523

DBF522

DBF521

DBF520

DBF519

DBF518

DBF517

F505

R752

R751

R639

R638

R628

R627

R626

R625

R624

R623

R622

R621

R619

R610

R648

R636

R653

R679

R644

C685

C707

C838

C857

C856

R772

F504

C839

C700

C706

C696

C695

R618

R617

R616

R615

R614

R696

R667

R668

R654

R665

R664

R637

C705

BF504

C821

C820

C819

C818

C817

C672

C671

C670

C669

C668

C574

C573

C572

C571

D505

D504

D503

D502

C542C542C542

C541

C540

C539

C555 C552 C547 C544

C537 C531 C528

C526 R530

C553 C548 C545 C538

R532R529

R531R535

R534

C518

C524

C535

C516

R522

IC502

R515R521

C515

R514

C514

R520

C523

C534

C522

R537

C513C521

C533

R519C517

R533

R513R518

IC501

C505

C501

D501

BF501

C512

R512

R504

C506

C588

R542R547

R541R546

C586R544

R540R543

C587R545

R548

C510R525

R524

C511

C520C532

C519R536

R517

C504

C503

TR502

TR501

C502

R505

C653

C652

C651

C657

C656

R596

OSCUSB1

R591

R590

R589

R588

R587

R586

R585

R584

R563

R561

C635

R560

C636

RM513

RM511

RM510

RM509

RM508

RM507

RM506

RM505

RM504

RM502

RM501

RM503

RM512

C543

C634

C666

C665

R603 R601

C664

C663

C662

C661

C660

C659

C658

C613

C603

C594

C581

C579

C609

C602

C597

C590

C585

C584

C577

C569

C583

C576

C568

C575

C567

C589

C582

C598

C596

C612

C614

C595

C605

C580

C566

C592

C578

C570

C593

C556

C565

C622

R555

R554

R553

C620

BF502

C619

C621

C601

C600

C549

C599

C608

C607

C606

C554

C564

C563

C562

C561

C560

C559

C558

C557

R539

R538

C551

C550

C549

C546

R508

R507

C508

R529

R528

R527

R526

RST501

R511

C591

C642

C643

SDRAM1

SDRAM2

SDRAM3

SDRAM4

C775

C776

C777

C720

C719

C644

F501

C615

C611C633

R594

R593

R592

C650

C836

C835

C836

C833

C840

C841

C760

C604

C610

IG501

C832

C837

C834

R747

R746

OSC1

C681

C682

C683

R633

R634

R632

C508

C646

R578

R579

C647

C645

C640

C639

C638

C637R604

R605

C673

C676

C675

C674

R609

C677

RM526

RM533

RM541

RM522

C655

R606

R646

C692

C678

C679

R607

RM527

RM586

RM588

RM587

RM565

RM562

R698

R705

C787

RM569

RM563

RM564

IGTD501

C842

RR501

RR502

RR503

C807

RM585

R699

RM554

RM568

C772

RM559

RM558

RM557

RM543

IC503

IC502

IC504

IC505

RM535

RM538

RM551

RM544

RM529

RM518

BE503

C648

C649

C828

C824

C825

C641

R567

R566

R580

R581

C627

C628

C626

C623

C624

C625

37

36

72

R767

C758

C759

1

144

73

109

108

L

A

N

IC

C726

BF505

R768

R701

R704

FUSE

C861

IC509

C767