The proportional band (Pb) is a temperature band

expressed in degrees. When the controller is within this

band, the time proprtioning functions are active.

Integral action (automatic reset) corrects for offset (load

error) for load variations. Reset wind-up inhibition prevents

integral action from occurring outside of the proportional

band. Software antisaturation minimizes process oscilla-

tions when the load changes.

Derivative action is adjusted to match the response time of

the process and to compensate the integral action.

Correct adjustment provides power output compensation

for process load variations. It also minimizes overshoot

and oscillations at start up or in large process upsets.

Refer to Figure 5.1 for additional adjustment instructions.

Manual Tuning Procedures:

For some systems it is difficult to execute automatic tuning

or the automatic tuning results are not satisfactory. The

following steps can then be used for initial tuning of a

three-mode control:

Step 1: Adjust the integral and derivative values to 0. This

inhibits the rate and reset action.

Step 2: Set an arbitrary value of proportional band and

monitor the control results.

Step 3: If the original setting introduces a large process

oscillation then gradually increase the proportional

band until the oscillation disappears.

Step 4: If the original setting does not introduce process

oscillations then gradually decrease the propor-

tional band until steady cycling is observed.

Record this important proportional band percent-

age (Pc).

Step 5: Time the period of steady cycling. Record this crit-

ical period Tc. The PID parameters are deter-

mined as:

This method was developed by Ziegler and Nichols.

If you are unfamiliar with tuning PID Controllers, we sug-

gest that you obtain and become familiar with the following

reference material: Tuning of Indusrial Control Systems

by A.R. Corripio ISBN: 1-55617-253-2-Q. Available from:

ISA Publications and Training Aids, phone: 919-549-8411.

This method should be performed with a temperature

chart recorder.

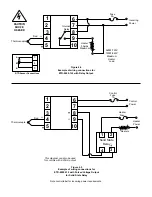

Fig. 5.2 Steady State Cycling

TIME

PV (Process value)

PV

Tc

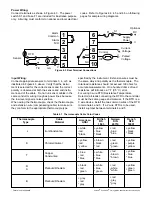

P Band (Pb) = 1.7 Pc

Integral Time (ti) = Tc

Derivative Time (td) = 0.125 Tc

PV

UPPER PB

SET POINT

LOWER PB

PI

PID

PD

P

OFFSET

PROPORTIONAL BAND

TIME

Perfect

Proportional Band Too Low

Proportional Band Too High

SP

PV

TIME

PROPORTIONAL ACTION

Derivative Too High

Perfect

Derivative Too Low

TIME

SP

PV

DERIVATIVE ACTION

INTEGRAL ACTION

PV

SP

Integral Too High (Too long for recovery)

Perfect

Integral Too Low

TIME

FIG 5.1 Effects of PID Adjustment on Process Response

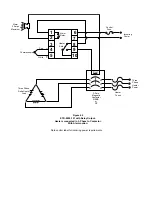

Fig. 5.3 Response of a Typical Control System Using Various Modes of Control