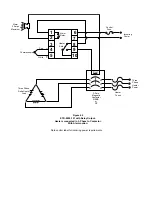

Ramp and Soak Function

The ETR-9090 can be programmed as either a fixed set

point controller or as a two segment ramp and soak

control. The ramp-up rate is determined by the “rr”

setting. This setting can be adjusted in the range of

0-360°F (200°C) per minute. The ramp rate function is

disabled if the “rr” is set to 0. The soak function is

accomplished by configuring the alarm relay to act as

timer. To use this function, set ALA1 to 12. The alarm

relay will be closed at start-up and it will stay closed

until the process temperature has remained at the set

point temperature for the time period set in ASP1. The

ASP1 setting is in minutes. When the alarm relay

opens, the process temperature will drop at an

uncontrolled rate. The heater power must be wired in

series from the main relay through the alarm relay. The

control will now operate as a guaranteed soak control.

Please note the following example: The ramp rate “rr”

is set to 5°F per minute. The ALA1 is set to 12, and the

ASP1 is set to 30 (minutes). When the unit is turned

on, the process will climb at 5°F per minute to the set

point of 175°F. Once the set point has been reached,

the timer will activate. After 30 minutes, the alarm

relay will open. The process temperature falls. The

process will repeat every time power has been switched

off and on to the controller. See Diagram 1 at right.

175

150

125

100

75

0

20

40

60

80

90

°

F

30 Minutes

Alarm Relay

OFF

TIME/Minutes

10

30

50

70

ON

Process Value

= 12

= 30

175

150

125

100

75

0

20

40

60

80

90

°

F

30 Minutes

Alarm Relay

OFF

TIME/Minutes

10

30

50

70

ON

Process Value

= 13

= 30

Set point

DIA. 2 Single Event

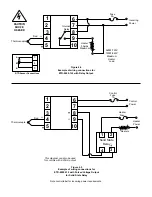

Single Event Function

The single event function may be used to control

external devices such as lights, bells or locks. It could

also be used to alert the operator when a guaranteed

soak time has been reached. To use this function, set

ALA1 to 13. The alarm relay will now operate as a

timer. The relay will be open at start-up. Once the set

point temperature has been reached and the time

period set in ASP1 has elapsed, the alarm relay will

close. The relay will remain closed until power to the

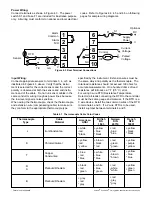

Table 5.7 (Continued)

Descriptions of Alarms

Process High Alarm: Alarm is actuated whenever the process value rises above the alarm set point. Changing

the control set point does not affect the process alarm trip point.

Process Low Alarm: Alarm is actuated whenever the process value falls below the alarm set point. Changing

the control set point does not affect the process alarm trip point.

Deviation High Alarm: Alarm is actuated whenever the process value goes above the control set point by a

predetermined (alarm Value) amount. Changing the control set point changes the alarm set point value

maintaining the same deviation from the control set point.

Deviation Low Alarm: alarm is actuated whenever the process value falls below the control set point by a

predetermined (alarm Value) amount. Changing the control set point changes the alarm set point value

maintaining the same deviation from the control set pint. This alarm value is a negative number.

Inhibited alarms do not energize the alarm relay the first

time the process temperature enters the alarm area.

From the second time the process temperature enters

the alarm area, the Inhibited Alarm offers ON as a nor-

mal alarm. For some systems, it is useful to bypass the

first alarm section while the system is heating up.

control has opened. The cycle will repeat each time the

control is energized. Note Diagram No. 2 below.

DIA. 1 Ramp and Soak