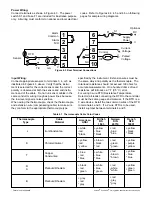

*Factory set before shipping.

**Process alarms are at fixed temperature points.

Deviation alarms move with set point value.

For convenience, values used can be recorded on the next page.

Long Scroll

Index

Description

*Default

Code

—Adjusting Range

Setting

Alarm Mode Selection**

0: Process High Alarm

1: Process Low Alarm

2: Deviation High Alarm

3: Deviation Low Alarm

2

4: Inhibited Process High Alarm

5: Inhibited Process Low Alarm

6: Inhibited Deviation High Alarm

7: Inhibited Deviation Low Alarm

8: Outband Alarm

9: Inband Alarm

10: Inhibit Outband Alarm

11: Inhibit Inband Alarm

12: Alarm Relay OFF as Dwell Time Out

13: Alarm Relay ON as Dwell Time Out

Hysteresis of Alarm

– 0 to 20.0% of SPAN

0.5

°C/°F Selection

– 0 to 1

0

0:°F, 1:°C

Resolution Selection

– 0 to 3

0: No Decimal Point Used

1: 1 Digit Decimal

2: 2 Digit Decimal

0

3: 3 Digit Decimal

2 and 3 can only be used for

Linear Voltage or Current

(IN=10)

Control Action

– 0 to 1

0: Direct (cooling) Action

1

1: Reverse (heating) Action

Error Protection

– 0 to 3

0: Control OFF, Alarm OFF

1: Control OFF, Alarm ON

1

2: Control ON, Alarm OFF

3: Control ON, Alarm ON

Hysteresis of ON-OFF control

– 0 to 20.0% of SPAN

0.5%

Low Limit of Range (SPAN)

Adjust for your process

–58

– See Instructions on Page 13.

High Limit of Range (SPAN)

Adjust for your process

1832

– See Instructions of Page 13

Low Calibration parameter

– Refer to Section 6.

32

High Calibration parameter

– Refer to Section 6.

1112

Index

Description

*Default

Code

—Adjusting Range

Setting

Set Point of control

SV

– Low Limit to High Limit Value

Alarm Set Point Value

– Low limit to high limit (If ALAI=0,1,4 or 5)

–0-3600 minutes (If ALAI=12 or 13)

18°F

–Low limit minus set point high limit minus

set point (IF ALAI=2, 3, 6 or 11)

Ramp Rate for the process value.

Limits an abrupt change of the

process temperature. (Soft start)

– 0-360°F 0-200°C/minute (If in=0-90)

0.0

– 0-3600°/minute (If in = 10)

Offset Value for Manual Reset

Only used if integral is 0.

0.0

– 0 to 100%

Offset shift for process value

– 199 count to 199 count

0.0

See page 18 for instructions

Proportional Band

0 - 360°F

For ON-OFF control set to 0

18.0

See instructions below.

Integral (Reset) Time, TI

– 0 to 3600 seconds

120 sec.

Derivative (Rate) Time, TD

– 0 to 1000 seconds

30 sec.

Local Mode

– 0 to 1-

0: No Control Parameters can be

1

changed.

1: Control Parameters can be

changed.

Following parameters will be

upgraded to Level 1

– 0 to 7

0: None

4:

0

1:

5:

2:

6:

3:

7:

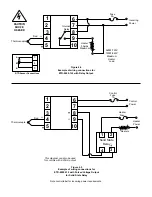

Proportional Cycle Time, Heating &

Cooling – 0 to 120 seconds

Relay

20

3-32VDC Pulsed Voltage

1

Linear Voltage, 4-20ma Current

0

Input Mode Selection, IN

– 0 to 10

5: R Type T/C

T/C

0

0: J Type T/C

6: S Type T/C

1: K Type T/C

7: N Type T/C

RTD

8

2: T Type T/C

8: PT100 DIN

3: E Type T/C

9: PT100, JIS

4: B Type T/C

10: Linear Voltage

Linear 10

or Current

NOTE: T/C - Close solder gap G5. RTD - Open G5

Located on P.C.B. A909F

Table 5.3 Index Code (Menu) Descriptions:

(Do not disconnect power for at least 12 seconds after changing any control values.

This allows the parameters to be entered into memory.)

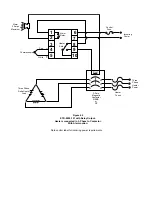

ON-OFF CONTROL:

For on-off control action the following parameters must

be set to zero (0): Proportional band, Integral, Derivative,

Cycle time, Offset. The hysteresis (deadband) adjust-

ment must now be used to determine the process oscil-

lations from set point. Setting the hysteresis to a larger

number will cause the contactor (or other equipment, to

switch less often, but the process will oscillate farther

from the set point.

NOTE: Further parameter definitions

on pages 12 and 13